Articles

ProAmpac’s Philosophy: Think Big, Act Small

While growing into a major force in flexible packaging—fueled by acquisition and new product development— this fully integrated film processor and converter has held onto the core values of a fast, feisty and customer-hungry smaller outfit.

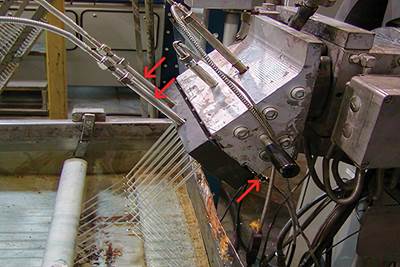

Read MoreSystem Moves Color Control From Lab to Production Floor

In-line spectrophotometer from Equitech promises to move color management out of the lab and right to the extrusion line to slash waste and improve quality.

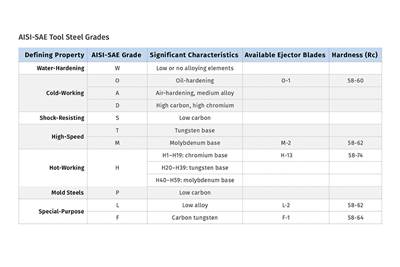

Read MoreWhat You Need to Know About Blade Ejectors: Part 2

Follow these guidelines to prevent premature wear, flash and galling.

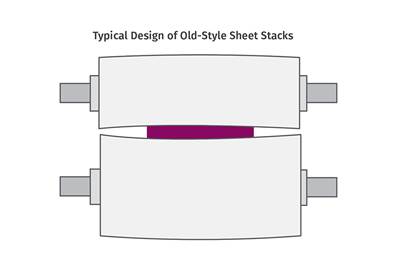

Read MoreUnderstanding Roll Deflection in Sheet Processing

Because of roll deflection, sheet stacks made for PS don’t work nearly as well with PP. One solution is to try a top roll that bends in the opposite direction.

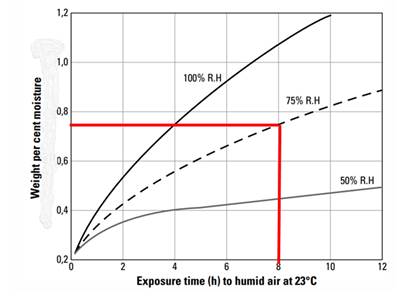

Read MoreFollow These Seven Management Tips for More Consistent Resin Drying

Equipment and advice sure help, but ultimately, good management makes the difference.

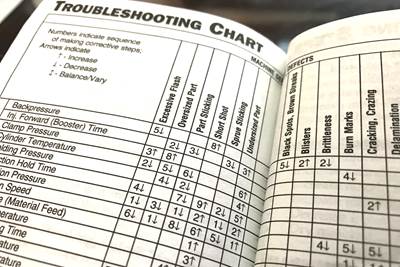

Read MoreApply the Power of a Troubleshooting Checklist to Your Process

Pocket guides provide processors an injection molding “crib sheet,” but in a process with thousands of interactions, applying if-this/then-that logic can’t always get you to a problem’s root cause.

Read MoreTracing the History of Polymeric Materials: Nylon

The story of nylon, the first true engineering thermoplastic.

Read MoreAutonomous Bin Picking Streamlines Downstream Operations for Molder

Allied Moulded Products saves labor and floorspace with Universal Robots’ new ActiNav autonomous bin-picking kit.

WatchCincinnati BAAM Technology Demonstrates 3D Printing with Recycled Materials

The demonstration successfully proved that large-scale multi-material printing can be done effectively and economically with recycled composite materials.

Read MoreComprehensive, Scientific Overview of Plastics and the Environment

Veteran plastics materials scientist tackles waste, litter, microplastics, degradation and other related topics in his book The Plastics Paradox

Read MoreGoing for the Green vs. Getting in the Hole

Too often when designing a tool or establishing a process, molders go for the hole in one when they only need to aim for the green.

Read More