Articles

Innovative Recycler Sets Sights on PET Thermoforms

Green Impact Plastics becomes first to focus on thermoforms in tray-to-tray recycling venture.

Read MoreDespite COVID-19, ERP Software Keeps Molder Working—Even from Home

ERP platform’s remote access, real-time operations overview, and transparency into production output and customer demand help custom molder weather coronavirus.

Read MoreShopping for a Barrel? Consider the Full Cost of Ownership

Beyond just the “invoice price” of a barrel, processors should consider factors like the composition of the inlay, quality of the backing material, straightness, concentricity, machining imperfections and packaging/handling, to understand the true cost of owning a barrel.

Read MoreHow to Ensure Reliable Feeder Performance When Handling PCR

Processors are being challenged to incorporate more recycled material into their products. Yet there are both economical and technical obstacles to achieving this objective—feeding among them. The design of your feeding equipment and the advantages that it will offer to your process will be more important than ever.

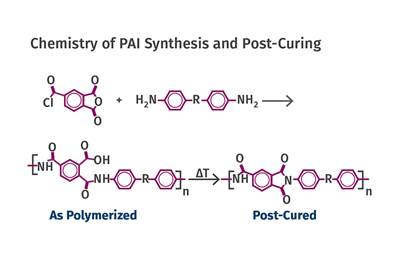

Read MoreMaterials: Annealing Tips for Polyamide-imide, Part 7 of 7

PAI is a material capable of achieving levels of performance that even semi-crystalline engineering polymers like PEEK, PPS, and PPA cannot. But you have to be willing to work for that performance, and the annealing process is an essential part of this.

Read MoreNovel Nozzle Tip Prevents Stringing, Saving Molds & Cycle Time

New design is said to eliminate mold damage from nozzle stringing or work-arounds that slow cycles.

Read MoreTop Shops 2020: Molding More from Less

Plastics Technology’s 2020 Top Shops benchmarking survey reveals that the most effective molders are, not surprisingly, the most efficient, accomplishing more than their peers from a smaller manufacturing footprint.

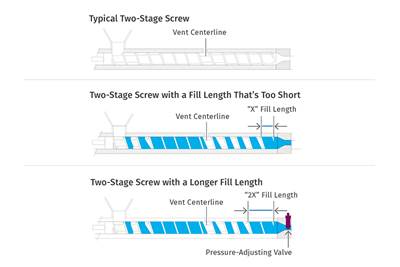

Read MoreExtrusion: Solving Surging in Two-Stage Screws

This usually crops up when the two stages are not matched in output. The best solution is to install a pressure-adjusting valve at the discharge end of the extruder.

Read More'10 Things We’re Seeing in Machine Shops Right Now'

Metalworking shops and plastics plants make for interesting comparisons of their responses to the COVID-19 challenge.

Read MoreNovel Dual-Wheel Blow Molder Allows Quick Product Changes

Two wheels, one extruder, two sets of molds: all you need to change products without a mold change.

Read MoreThe Buck Stops … at This One-Stop Compounder

CRC Polymer Systems brings expertise in material selection, product formulation and processing, and a thorough understanding of part design and tooling under one roof with a series of customized materials and capabilities aimed at OEMs and molders.

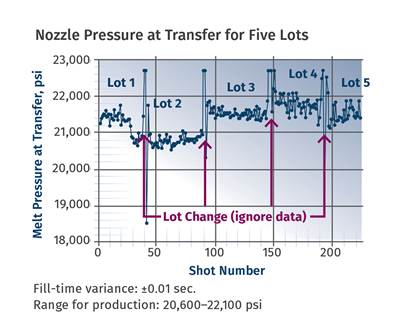

Read MoreHow to Know When Your Process is Ready to Make Acceptable Parts

Focus on six key metrics to help you determine when a process is lined out and stable enough to start production.

Read More