Articles

Processing Medical Plastics? Here's How to Minimize Risk

FDA now expects OEMs of healthcare products to also take responsibility for Tier 2 and 3 suppliers—making sure every supply-chain link is meeting Good Manufacturing Practices.

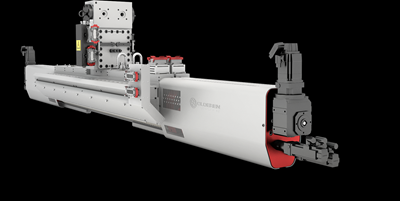

Read More‘Game Changing’ Flat Die Lives Up to Its Billing

Revolutionary ‘touchless’ die and control system for cast film and coating/laminating offer speed, efficiency and operational efficiencies to processors that were previously ‘unheard of.’

Read MorePrices Up for Nearly All Major Volume Resins--For Now

As the third quarter was coming to an end, prices of nearly all volume resins were higher or heading that way. But flat or even lower prices are seen ahead.

Read MorePlastics Processors Report Quickening Expansion

Expansion among both captive and custom processors is driven by expanding orders, production, and employment.

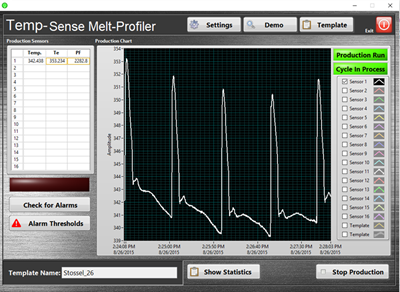

Read MoreMelt-Temperature Measurement Shows New Potential for Monitoring & Control

Unique melt-measurement system provides new types of data for quality and process control. A new version is coming soon.

WatchMaking Cooling Time Productive With a Shuttle Mold System

The Shuttle Mold system enables users to inject parts in two molds with a single injector, turning cooling time for one part into productive time for another.

WatchA Window of Opportunity Opens to One Million Parts a Day

Injection molder and moldmaker Lawrence Industries was founded on the promise of plastics as a replacement for metal in window hardware—a market it now dominates.

Read MoreGraphene Nanomodified Glass-Reinforced Nylon 66 Holds Much Promise for New Automotive Applications

OCSiAl’s Tuball graphene nanotubes are used by composites compounder in a line of glass-filled nylon 66, with other polymer developments underway.

Read MoreIneos Styrolution Talks Closing the Loop on Polystyrene

The company is collaborating with several companies on several solutions, including depolymerization.

Read MoreFive Ways SPC Can Improve Performance

Statistical process control (SPC) can help plastics processors determine the factors responsible for product quality variation and provide a roadmap for improving the production process.

Read MoreRunning PCR? Optimize Performance & Processability with Stabilizers

Proper stabilization of PCR is vital to enable production of molded and extruded parts to meet brand-owner requirements.

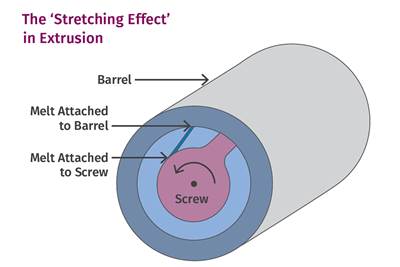

Read MoreUnderstanding the Effect of Polymer Viscosity on Melt Temperature

Every processor should get hold of the viscosity curves for the polymers they use or contemplate using in their operations, and learn how to read them.

Read More