Creating a Connected Workforce that Maximizes Productivity & Profitability

Most people find is that it’s hard to monetize something when they don’t know how much they’re wasting.

Historically, spending on quality in manufacturing is anywhere from 15-20% of sales. But in the 1990s, lean manufacturing heightened manufacturers’ focus on cutting waste and reducing cost. So why is spending on quality still 15-20% of sales today?

For example: If you’re a molder, you’re likely under intense pressure to cut long cycle times or increase productivity to keep part-piece prices low or meet production volumes. Typical changeover times can take up to an hour or there can be several changeovers per day. What are you doing with the excess virgin and purge materials during these changeovers? Do you know these costs? You may also struggle to implement new technologies because you lack adequate cost savings programs.

During ISO audits, I usually say, start with one relatively simple thing: “Eliminate the waste that you have within your own company.”

A lot goes into it, but most people find is that it’s hard to monetize something when they don’t know how much they’re wasting. It’s staggering the number of things people don’t measure. If I ask a processor, “How much material do you deliver to the hopper of Machine 14?” They’ll say, “Well, the costing department, they add in 10% to the material costs to be able to take care of handling, and for extra startup, they add 10% scrap to the customer’s purchase price, so, it’s not hurting me.” That’s great that you’re not losing money generating waste. But if you think of it the other way around, how much more money would you make? The slogan that I use is “Let’s look at the money you’re losing.”

One of the ideas that I’m trying to push through is to be able to set up a repelletization organization where there’s certain materials that, to be able to use them efficiently, you’re going to have to bring them in and regrind and pelletize. SD Polymers is just that reprocessor in Macon, Georgia. They can collect that scrap and regrind parts from suppliers from all over the place, and they participate in making sure they keep it clean, keep it marked and keep it separated. SD Polymers can repelletize it and sell it back, and that would take care of a huge amount of waste. This facility will tremendously help in serving the plastics recycling and renewal needs.

Plastics processors (molders and extruders) are acutely aware that audits and claims are just part of 911爆料网. At the same time, they all agree that the best way to deal with complaints and cost related programs is to prevent them in the first place. Because today’s manufacturers operate on razor-thin margins with little room for error, a reactionary approach to quality and recycling management is a massive bottom-line profit improvement.

Learn how this closed loop solution ultimately results in higher ROI from all your systems, working together to generate and analyze the data, ultimately driving long term improvement. This leads to faster problem resolution and new product introduction, which ultimately results in higher quality, customer satisfaction and loyalty and improved brand perception.

About the Author: Lewis Yasenchak, MBA, BS is the founder/owner of P&Y Management Resources, which specializes in building and improving the plastics industry supply chain. He’s has worked for Veteran of Johnson & Johnson, Hoechst-Celanese and Rehau/RAUMEDIC at their corporate offices in New Jersey. Project/Product management positions coordinating activities in the United States with Germany and Switzerland participation. Contact: lewis.yasenchak@windstream.net.

Related Content

Educational Grant and Student Scholarships Open

The Society of Plastics Engineers’ Mold Technologies division is accepting applications for a $5,000 educational grant and a new $3,000 student scholarship honoring Glenn Beall.

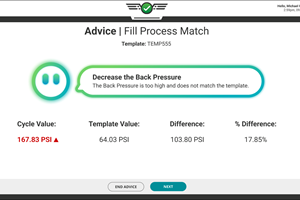

Read MoreSmart Assistant Bridges Injection Molding Skills Gap

NPE2024: MAX the Process Advisor, as well as free presentations and training by RJG Inc.

Read MoreCommunity College Launches Injection Molding Bootcamp

Nebraska’s Central Community College, which has become a centrally located training hub, successfully launched a plastics bootcamp this summer, boosting available workforce for regional molders.

Read MoreIn-Person Training Course Tackles Plastics Material Selection

The Madison Group plastics consultancy has created a two-and-a-half day in-person course to be held in Minneapolis that aims to help attendees develop a systematic and optimized approach to plastic material selection.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More