50 Ideas That Changed Plastics

Very few readers of this issue can remember, or even imagine, what it was like when an injection molding machine did not have a screw, but only a smooth-bore plunger.

- Blow Molding

- Molds & Tooling

- Compounding

- Tooling

- Thermoforming

- Extrusion

- Film Extrusion

- Injection Molding

- Additives

- Processes

- Stretch Blow Molding

- Postconsumer

- Sheet Extrusion

- Recycling

- Barrier Blow Molding

- nanocomposites

- Automation

- Postindustrial

- sustainability

- Postprocessing

- Commodity Resins

- Hot Runners

- monitoring

- Multiscrew

- In-Mold Decorating

- polyolefins

- Mold Simulation

- Processes

- Pipe, Profile & Tubing Extrusion

- Multicomponent

- Gas & Water Assist

- All Electric & Hybrid Machines

Very few readers of this issue can remember, or even imagine, what it was like when an injection molding machine did not have a screw, but only a smooth-bore plunger. Very few can remember a time when there were no twin-screw extruders; no multi-layer film, sheet, or bottles; no accumulator-head or injection blow molders; no polypropylene, HDPE, or polycarbonate; and no such thing as RIM or rotomolding or structural foam—or even a melt indexer. How and when these technologies got started are just some of the little-known stories that are told in the following pages. Fifty stories, in fact—one for each year this magazine has been reporting on the latest ways to manufacture with plastics.

So many essential technologies surfaced in the last half-century that it was perplexingly difficult to select just 50 to celebrate here. We invited long-time industry experts in all areas of plastics to help us make those choices. Turn the page to see who they are.

Even with the help of nearly 2000 years of collective plastics experience, our editors had to make some tough calls. For example, we ruled out microprocessor controls because the computer revolution has had a universal impact, and plastics rode the wave along with every other industry. Likewise, we left out printing and decorating technologies because they had prior history with other materials. We also had to skip worthy candidates in some fields so as to broaden our coverage to all areas of plastics. Please note that we have not presented these 50 innovations in any particular order, except for the first four, which did pull the most votes.

Some readers may disagree with our choices, and some may argue over who deserves pioneering credit in a particular field. Our editors found it much harder than expected to retrace the history of these 50 innovations. So few eyewitnesses to this history are still accessible for interviews. Relatively little has been published on this field of technological history. And many records were lost or discarded in the myriad corporate mergers over the decades. So we often had to rely on individuals’ memories of past decades. And we had to resolve inevitable disagreements over some dates and facts.

You’ll see that it was worth it. These are important stories. They reveal the origins of so much that we take for granted—in brilliant intuition, hard work, or plain good luck.

Top 50 Innovations

- Reciprocating Screw Injection

- Polypropylene

- HDPE

- Polycarbonate

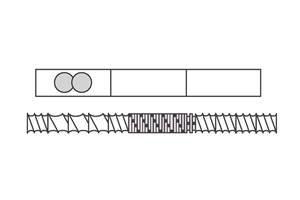

- Twin-Screw Extrusion

- LLDPE

- Sheet Molding Compound

- Ultrasonic Welding

- Stretch-Blow Molding

- Desiccant Dryers

- ABS Resins

- Parison Programming

- Structural Foam

- Barrier Screws

- Accumulator-Head Blow Molding

- Super-High-Heat Thermoplastics

- Melt Indexers

- Carbon Fiber

- Injection Molding Simulation

- Thermoplastic Elastomers

- Hot Runners

- Takeout Robots

- Pressure Forming

- Rotary Thermoforming

- Halogenated Flame Retardants

- PET and PBT

- Film/Sheet Coextrusion

- Multi-Material Injection

- Multi-Layer Blow Molding

- Hindered Phenolic Antioxidants

- HALS UV Stabilizers

- All-Electric Injection Presses

- Rotational Molding

- Gas-Assist Molding

- In-Mold Decorating & Labeling

- Cavity-Pressure Sensing

- Spray-Up Composites

- Injection Blow Molding

- Pur Thermal Insulation

- RIM

- Foam Extrusion

- Underwater Pelletizing

- Chemical Blowing Agents

- Spiral Dies for Pipe & Blown Film

- Auto Gauge Control for Blown Film

- Auto Gauge Control for Flat Dies

- Biaxial Film Orientation

- Film/Sheet Thickness Sensors

- Density Separation of Mixed Waste

- Computerized Color Matching

Related Content

Engineering Resins Compounder Expands to Take on More Scrap

Polymer Resources responds to sustainability push by upgrading plant with grinding and shredding equipment to take on both postindustrial and postconsumer reclaim.

Read MoreConfiguring the Twin Screw Extruder: Part 4

For many compounding operations, material is fed to the extruder at the feed throat. This is the case when feeding a single polymer or a blend of polymers mixed with solid additives. Some ingredients, however, present a challenge in feeding. Here’s how to solve to them.

Read MoreOptimizing Melt-Fed Single-Screw Extruders on Compounding Lines

The main problem with melt-fed extruders that are starve-fed is setting the depth of the metering channel. In this scenario, we describe how this problem was solved.

Read MoreUnderstanding 'Boundary Conditions' in Twin-Screw Compounding

In twin-screw compounding, the objective is generally to produce the highest quality product at the maximum strand. But sometimes there are operating parameters that prevent this objective from being realized.

Read MoreRead Next

OPP Bottles: Has Their Time Come?

Maybe this time the often-predicted breakthrough will actually occur. What could make the difference are improved resins, clarifiers, and machinery.

Read MoreBarrier Bottle Technologies Square Off

With single-serve containers raising shelf-life demands, packagers are seeking the barrier with the best cost-performance for PET bottles. Multilayer seems to have the upper hand, but monolayer, coating, and oxygen-scavenger technologies have all won niches.

Read MoreIn-Mold Labeling Catching on in North America

Already a familiar sight on European store shelves, the eye-catching appeal of "IML" is gaining traction among North American injection molders. The latest tooling and automation designs can handle the higher volumes needed here.

Read More