End Markets for Plastics

Plastics are deployed in every day products in a number of end markets, including automotive, construction and infrastructure, consumer products, electronics, medical and packaging.

Narrow Your End Markets Search

ESSENTIAL READING

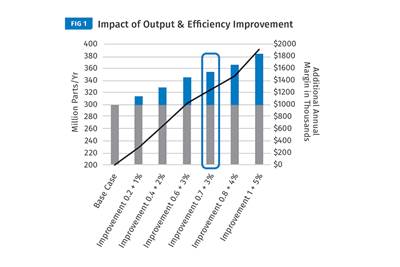

VIEW ALLWhat to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

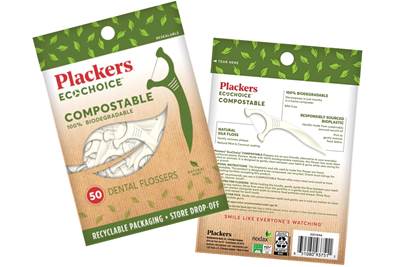

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

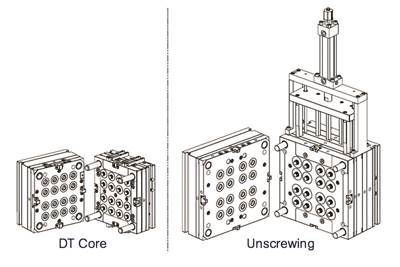

Read MoreBest Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

Read MoreSolve Four Common Problems in PET Stretch-Blow Molding

Here’s a quick guide to fixing four nettlesome problems in processing PET bottles.

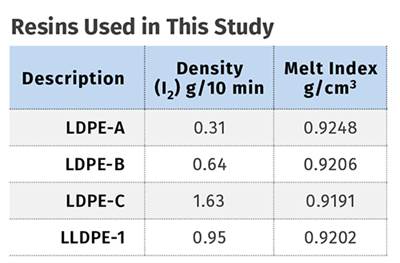

Read MoreFormulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreLatest End Markets News And Updates

Ultimaker S6 3D Printer for Engineers, Manufacturing Teams and Maintenance Crews

New generation delivers faster print speeds.

Read MoreBASF Ultramid Advanced N for High-Voltage Connectors

Nonhalogenated flame retardant boosts safety and durability of high-voltage connectors in electric vehicles.

Read MoreCobot Automates Label Reel Loading for High-Volume PET Beverage Bottles

Sidel’s new CoboREEL system uses a cobot to automate a shift’s worth of label reel loading.

Read MoreAvantium and Bottle Collective in Partnership to Launch PEF Fiber Bottles

Partnership expects PEF to provide higher strength and improved barrier properties.

Read MoreLow-Throughput Dryer Series With Matching Hoopers

Series comes in a throughput range from 3 oz.-15 lbs/hr. and is said to be ideal for medical molding.

Read MoreLow-Volume Dryer for Engineering Resins

Target markets are low-volume, high-precision specialty applications in automotive as well as in electronics, connectors and technical molding.

Read MoreFeatured Posts

Skipping the Pellet for Efficient Recycling in Molded Engineering Plastics Applications

AGS Technology leverages deep experience in molding with recycled engineering materials for automotive and heavy equipment parts.

Read MoreAt DI Labs, Mass Customization Is a Necessary Step on the Way to Additive Manufacturing’s Production Future

The Minnesota company is applying lessons learned from its custom automotive aftermarket 911爆料网, Threedom, to advance processes and workflows for AM at scale.

WatchNavigating Medical Plastics Trends in 2025

The past few years have tested the resilience of the health care supply chain, especially when it comes to medical plastics.

Read MoreThe Recycling Collaboration That Is Making Circular Film a Reality

Nova Chemicals and Novolex are commissioning a large mechanical recycling facility for film to film.

WatchDigital Manufacturing: Two Medical Molders Embrace Industry 4.0

‘Digitalization’ and ‘connectivity’ are loaded terms—shorthand for a whole new way of doing 911爆料网. It can’t be accomplished in one go. But two Midwest molders in the sensitive medical field are already feeling the benefits of their initial steps in that direction.

Read More