Getting the Most Out of Injection Molding Simulation

Multiple speakers at Molding 2023 will address the ways simulation can impact material substitution decisions, process profitability and simplification of mold design.

Simulation has long been a powerful tool allowing molders to pinpoint potential design and process pitfalls on a computer screen — before mold steel has been cut — instead of discovering them on the production floor, when the time and cost to fix the issue(s) quickly becomes prohibitive. As the technology advances, it provides molders even greater capabilities, giving them new tools to apply.

At (Hyatt Regency Minneapolis; August 29-30), multiple speakers will address different ways simulation can positively impact injection molding operations.

- — David Corsi, Beaumont Technologies

- — Todd Bryant, Paulson

- — Christopher Blake, Maya HTT

Learn more about , which will be collocating with MoldMaking Technology magazine’s (registrants to either event can attend both), including speakers addressing sustainability and automation.

Attendees to Moldmaking 2023 (August 29-30; Minneapolis, Minn.) will see multiple presentations touching on the role of simulation in injection molding today.

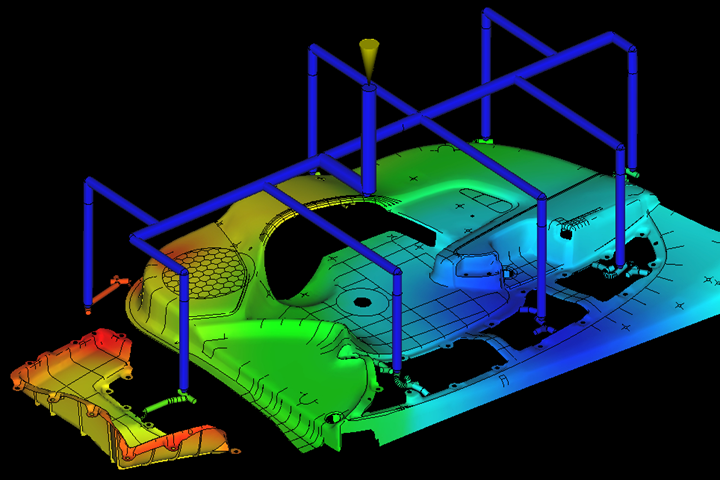

Photo Credit: Autodesk Moldflow

Related Content

-

Hot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.

-

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

-

Understanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?