Plastics Use in the Medical Industry

Plastics play a huge part in the medical industry, including in catheters, IV bags, blood bags, ventilators, syringes and hospital beds.

ESSENTIAL READING

VIEW ALLWhat to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

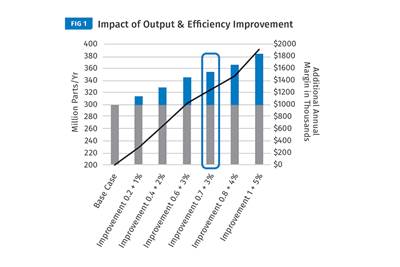

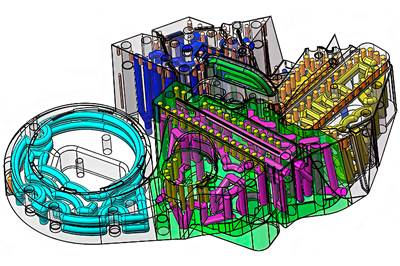

Read MoreHow to Know the True Value of Conformally Cooled Injection Molds

What’s the return on investing in a new mold with conformal cooling to boost productivity? Will it pay for itself? How soon? Here’s a case study on how to answer those questions.

Read MoreProtolabs Addresses How to Survive a Pandemic with Digital Manufacturing

Protolabs survey results examine product development and the supply chain.

Read MoreProcessing Medical Plastics? Here's How to Minimize Risk

FDA now expects OEMs of healthcare products to also take responsibility for Tier 2 and 3 suppliers—making sure every supply-chain link is meeting Good Manufacturing Practices.

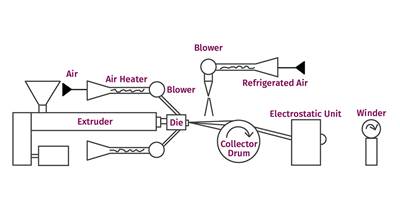

Read MoreExtrusion: 'Melt-Blown' Fiber: What You Need to Know to Enter the Face Mask Market

Coronavirus pandemic has made extrusion processors curious about entering the face-mask market. But melt-blown fiber is very different from most other extrusion processes and requires specialized equipment.

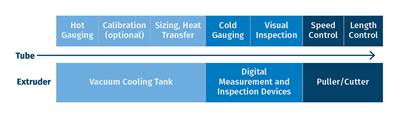

Read MoreHow to Improve Production of Catheters and Stents

Advances in downstream extrusion equipment have boosted production control.

Read MoreLatest Medical News And Updates

Arterex Acquires Italian Medical Device Provider

Arterex’s acquisition of Phoenix S.r.l. continues its growth mission to offer customers in North America and Europe diversified, high-precision medical device manufacturing solutions.

Read MoreAvient Colorant Chromatics PEEK Provides Biocompatibility in Health Care Applications

Precolored compounds and colorants for medical devices.

Read MoreMedical Grade TPEs for Biopharmaceutical Tubing

Teknor Apex expands its Medalist TPE portfolio.

Read MoreOCSiAl Opens First Large-Scale Graphene Nanotube Plant

The new facility in Serbia will serve Europe, North America and Asia to drive advances in plastics and rubbers.

Read MoreCompact Solution for Two-Component Molding

Zahoransky’s new internal mold handling technology foregoes the time, space and money required for core-back, rotary table or index plate technologies for 2K molding.

Read MoreExpanded Line of ‘Super’ Soft TPEs for Medical Devices

Kraiburg TPE has expanded its Thermolast M series of TPE compounds by additional hardness degrees.

Read MoreFeatured Posts

Digital Manufacturing: Two Medical Molders Embrace Industry 4.0

‘Digitalization’ and ‘connectivity’ are loaded terms—shorthand for a whole new way of doing 911爆料网. It can’t be accomplished in one go. But two Midwest molders in the sensitive medical field are already feeling the benefits of their initial steps in that direction.

Read MoreMedical and Molding Elite

When Jeff Smith received a notice evicting his promising 911爆料网 out of his house, it could have been the end of Elite Biomedical Solutions’ and Elite Precision Plastics’ stories before they really got started, instead it was just the beginning.

Watch3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

Read MoreIndustrial Resin Recycling Diversifies by Looking Beyond Automotive

Recycler equips for new 911爆料网 in medical, housewares and carpeting.

Read MoreCustom Molder Pivots When States Squelch Thriving Single-Use Bottle Business

Currier Plastics had a major stake in small hotel amenity bottles until state legislators banned them. Here’s how Currier adapted to that challenge.

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read More