Plastics Use in the Packaging Industry

Plastics are used to manufacture flexible packaging and rigid packaging in applications like caps, closures, bottles, film, and sheet.

ESSENTIAL READING

VIEW ALLHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

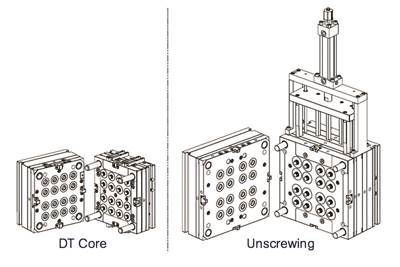

Read MoreBest Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

Read MoreSolve Four Common Problems in PET Stretch-Blow Molding

Here’s a quick guide to fixing four nettlesome problems in processing PET bottles.

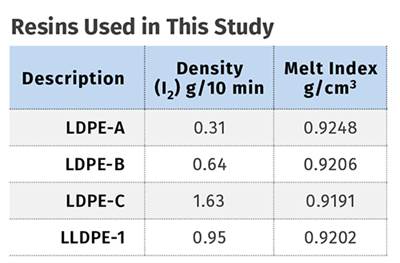

Read MoreFormulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreProtolabs Addresses How to Survive a Pandemic with Digital Manufacturing

Protolabs survey results examine product development and the supply chain.

Read MoreWhat Plastics Processors Need to Know about Tax Reform and Equipment Acquisition

The Tax Cuts and Jobs Act of 2018 (TCJA) is positioning plastics processors for more growth and profitability following the most recent Plastics Processing Index showing the best quarter since 2013 when the index began.

Read MoreLatest Packaging News And Updates

Ultralight PET Preform Design

The Factor 101 design created by KHS and Husky uses just 5.89 g of material to hold 591 mL of product — equivalent to a 20-ounce water bottle.

Read MorePrecision Concepts Buys Meredith-Springfield

Latest acquisition by this diversified producer of rigid packaging is a Northeast leader in technical blow molding.

Read MoreUniloy Celebrates 75th Anniversary

America’s first and oldest blow molding machine supplier marks a milestone.

Read MoreHusky Expands Facilities and Services in India

The company says its expanded presence in India helps clients meet the country’s sustainability mandates — which require 30% recycled plastic content in packaging by 2026 and 60% by 2029.

Read MoreSumitomo (SHI) Demag North America Names New Executive Leadership

The company has appointed Liam Burns to serve as president and John F. Martich III to serve in the expanded role of chief operating officer.

Read MoreAll-Electric Injection Machines Enable More Sustainable, Energy-Efficient Processing

Stork’s all-electric injection molding machines include a breaking energy feedback system in which recovered energy can be fed back into the customer energy grid.

Read MoreFeatured Posts

The Recycling Collaboration That Is Making Circular Film a Reality

Nova Chemicals and Novolex are commissioning a large mechanical recycling facility for film to film.

WatchThe Middle Way, Dissolution Recycling Technologies Leave the Polymer Intact

Alternative approaches can produce high yield and high purity with reduced energy demand.

Read MoreIs There a Better Way to Heat PET Preforms for Stretch-Blow Molding?

Is near-infrared (NIR) heating better, faster and more energy efficient? So far, only two machine builders are making such claims for NIR in place of standard mid-infrared preform heating, though their systems appear to be well accepted. Meanwhile, an altogether different alternative is in the works.

Read MorePackaging Converter Adopts PE-Based Vacuum Skin Packaging (VSP) for Food Applications

Videplast and ExxonMobil collaborated on the development of this cost-effective VSP film solution that contains no ionomers.

Read MoreResearch Deems Bioplastics, Wood Pulp a Sustainable, Economic Alternative for Rigid Packaging

Farrel Pomini and FPInnovations produce biodegradable compound for molding, extrusion and thermoforming applications.

Read MoreCustom Molder Pivots When States Squelch Thriving Single-Use Bottle Business

Currier Plastics had a major stake in small hotel amenity bottles until state legislators banned them. Here’s how Currier adapted to that challenge.

Read MoreFAQ: Packaging

The following are four other common issues, applicable to both single- and two-stage processes.

-

Pearlescence and haze

-

Insufficient top-load strength

-

Insufficient base clearance or rocker bottom

-

Drop-impact failure