Research Deems Bioplastics, Wood Pulp a Sustainable, Economic Alternative for Rigid Packaging

Farrel Pomini and FPInnovations produce biodegradable compound for molding, extrusion and thermoforming applications.

Recent research conducted by Farrel Pomini, FPInnovations and a consortium of industry leaders have reportedly demonstrated the commercial viability of biobased, compostable compounds such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) mixed with high levels of fiber in a variety of disposable packaging products, paving the way for eco-friendly products like food trays and disposable cutlery (Figure 1).

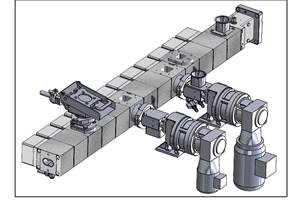

Compounding equipment builder Farrel Pomini and Montreal-based , the world’s largest nonprofit research technology organization for forestry, have proven the technology to produce industrial-grade biobased compounds with fiber content up to 60%. The compounds, produced on the Farrel Continuous Mixer, have been used to manufacture various products, including injection-molded disposable knives with up to 40% fiber, extruded sheets and thermoformed parts with fiber content ranging from 0.5% to 10%.

FIG 1 Applications for bioresin and wood pulp compounds include disposable cutlery. Source: FPInnovations

The final products are odor-free with light coloration, attributed low processing temperatures. Dr. Peng Ye, applications development manager for Farrel Pomini, presented the results of this project in May in Orlando, Florida, during NPE2024.

Leveraging Cellulose From Wood Pulp

Development of these cellulose-filled biodegradable resins is a result of a collaborative effort led by FPInnovations, based in Montreal. Farrel Pomini played a crucial role in producing these compounds at pilot and industrial scales using its continuous mixing technology at its lab in Ansonia, Connecticut.

The key to these innovations lies in using refined wood pulp, sourced for this collaboration from sawmill residue provided by West Fraser, a major wood products company. This refined wood pulp undergoes a process that removes most of the lignin, leaving cellulose and hemicellulose.

The low-lignin content of this wood pulp makes it suitable for food contact applications, and enhances processing conditions and heat resistance. Moreover, its wide commercial availability and inherent compostability make it an well suited for sustainable everyday products solutions, notes Dr. Yann Gabet, FPInnovations’ senior scientist and the project leader for the Biocomposites Initiative.

Farrel Pomini and FP Innovations found that adding cellulose fibers in PLA and PHA compounds provided several advantages, notably:

- High dispersion quality: The compounds demonstrate excellent dispersion up to 60% cellulose content.

- Enhanced heat resistance: The heat deflection temperature (HDT) of crystalline PLA-based parts significantly improves with the addition of cellulose fiber, surpassing 100°C with 5% wood pulp and reaching 150°C with 20% pulp content. This makes the compounds suitable for hot food and liquid contact applications (see Figure 2).

- Mechanical properties: Adding up to 5% wood pulp maintains or enhances tensile modulus, tensile strength and impact resistance without significantly affecting elongation properties (see Figure 3).

Ye and Gabet note that a critical feature of these cellulose-filled PLA compounds is their accelerated biodegradation compared to pure PLA. Testing conducted in accordance with ISO 14855-1 standards showed that PLA compounds with 20% cellulose demonstrated a faster biodegradation rate within the first 25 days compared to PLA alone. Additionally, compounds with 5% of another type of cellulose product achieved 90% biodegradation nearly 30 days earlier than pure PLA.

Moreover, according to Ye, Farrel Pomini’s compounding technology helps reduce the impact of the compounding process on sensitive materials (like cellulose and biopolymers) by utilizing low processing temperatures. This process also enables a reduction in moisture content from an initial 3% to 4% in the fiber to a final compound moisture of 0.05% to 0.1%.

FIG 3 Adding up to 5% wood pulp maintains or enhances tensile modulus, tensile strength and impact resistance without significantly affecting elongation properties.

FIG 3 Adding up to 5% wood pulp maintains or enhances tensile modulus, tensile strength and impact resistance without significantly affecting elongation properties.The Farrel Continuous Mixer (FCM) is a continuous compounder well suited to processing highly filled, temperature/shear-sensitive applications and excels at processing biodegradable plastics in addition to white and black masterbatches, PVC, flooring, halogen-free flame-retardant compounds, and wire and cable applications.

The FCM melts feedstock resins and homogenizes them under specific temperature and pressure parameters. Ye explains that the mixer’s low process temperature, short residence time and efficient rotor shear make it well suited for processing temperature-sensitive materials or materials with prior heat history. The mixer has been used to process PLA, PHA, PBS, recycled PVC and film scrap.

Environmental and Economic Benefits

Incorporating cellulose fibers into biodegradable resins offers several economic and environmental advantages, the partners in this project determine. These include:

- Lower costs compared to pure biopolymer

- Improved compostability of final products

- Optimized mechanical properties

- Improved heat resistance

- Lower carbon footprint

States Gabet, “The successful development and scaling of cellulose-filled biodegradable resins highlights a significant leap towards sustainable solutions for plastic-based everyday products. By combining innovative technology with the abundant resource of wood pulp, these advancements offer a practical and environmentally friendly alternative for various applications.”

Related Content

Configuring the Twin Screw Extruder: Part 4

For many compounding operations, material is fed to the extruder at the feed throat. This is the case when feeding a single polymer or a blend of polymers mixed with solid additives. Some ingredients, however, present a challenge in feeding. Here’s how to solve to them.

Read MoreHow to Configure Your Twin-Screw Barrel Layout

In twin-screw compounding, most engineers recognize the benefits of being able to configure screw elements. Here’s what you need to know about sequencing barrel sections.

Read MoreProcessing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreStrategically Manage Pressure to Help Ensure Quality in Co-Rotating Twin-Screw Extrusion

Pressure measurement provides an invaluable window into any extrusion process, but it must also be strategically managed at every stage of the process to ensure a quality part is being extruded.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More