AdvanTech Hopes To Open Up New Closure Market

CAPS AND CLOSURES

A linerless, one-piece injection molded cap for carbonated soft drinks cuts weight dramatically.

This month, a completely new concept in carbonated soft-drink (CSD) closures, promising equal or greater performance from less resin, will begin commercial production in Woodstock, Ill. , via its AdvanTech Closures LLC 911±¬ÁĎÍř, will introduce a one-piece, linerless, injection molded PE closure to North America, competing with the market’s standard two-piece PP cap with elastomer liner.

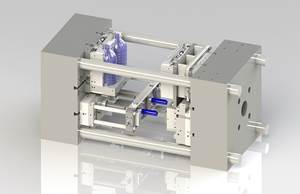

Al Zoller, CEO of AdvanTech, recently gave Plastics Technology a first look at the type of molding cell that would produce the revolutionary cap. Located in the company’s newest facility, just a six-minute drive from its custom molding operation in Woodstock, the cell is built around a HyCap 400 press from , running a 96-cavity tool from Austria’s .

Originally introduced in 2011, with early adopters in Australia and parts of Asia, the single-piece 1881 CSD finish standard marked a wholesale departure from the two-piece elastomer liner and PP cap, which still dominates the market. AdvanTech’s second-generation 1881 cap, with patented Flex Seal technology, has evolved further still, cutting weight by 20% from the first-generation 1881, down to just 2.1 g.

After exhaustive testing, including integration into bottling and filling plants, the cap received final approval from a major soft-drink manufacturer this year and will go into production when several of that company’s closure contracts are up for bid. This sets up 2016 as the year that one-piece injection molded CSD closures could establish a beachhead in North America. Before that was possible, the new design had to be completely vetted, with comprehensive testing, including application torque, removal torque, carbonation, carbon dioxide retention, and every imaginable dimension verified on all 96 cavities of the production tool.

SEEKING CLOSURE FOR A NEW CLOSURE

In 2001, Zoller took over the company that he would eventually rename AdvanTech in 2005. The company’s original building, which covers 27,000 ft2, is more than 70 years old and was home to the former Plasticraft tool shop. This facility, which houses 17 presses ranging from 55 to 400 tons, runs a variety of jobs from automotive to medical. In 2012, AdvanTech added a second plant three miles away, which covers 65,000 ft2, and is home to the linerless closure program. At present, AdvanTech is occupying only about 60% of that facility with six presses, ranging from 300 to 400 tons.

The new facility’s three rail spurs and six material silos were of particular interest to Zoller, given his ambitious closure-molding plans. “It’s built to do this kind of large-scale molding operation,” Zoller said of the site. If the linerless cap launch goes well, three fully equipped cells with a total of six machines will handle production with two 96-cavity molds and one printing line, Zoller said. The laser-printing operation will eventually include the ability to add barcodes to the underside of the closures, which can be scanned by consumers as part of the soft-drink maker’s promotional activities.

The 96-cavity tool runs a 3.7-sec cycle. Parts are fed to the printer, which can run up to three colors at 3000 pieces/ min. Since the mold can create more than 1500 caps/min, two molding machines can feed a single printer with the new closure.

In operation, the 96-cavity tool drops closures onto a conveyor, which feeds into a “waterfall” post-mold cooling system. From there, caps are oriented right-side-up and lined up single file for top printing via technology from ., Twinsburg, Ohio. A vision system from Swiss firm performs 100% inspection and rejects faulty closures for print defects or dimensional deviance. AdvanTech has multiple closure customers, including ones for hot-fill caps with metal inserts and large 63-mm closures for products like jelly.

SEEKING A NEW STANDARD

“The current caps, which are a heavier design, are molded in PP,” Zoller said. “The trend is towards HDPE, which we are using. There’s a variety of dynamic characteristics that really allow HDPE to be more effective in the one-piece sealing system.”

Noting that CSD bottles with the new caps should be on store shelves this month, Zoller is optimistic that his company is at the forefront of a step change for the sector. “We are hoping that the industry will to want to standardize on new caps, and this design is one of them,” Zoller said. “We’re up for being chosen to be one of the designs to be standardized on, and because of that, we anticipate big growth.”

How big? According to an April 2015 report by market researcher Freedonia Group, Cleveland, global demand for caps and closures is pegged to increase 5.6%/yr to $58 billion by 2019, with unit production rising 4% to 2.2 trillion. Beer, CSD, and bottled water represent the largest segments.

The market is also big enough to spur competition. In 2013, Closure Systems International (CSI) in Indianapolis introduced a compression molded, one-piece, linerless 28-mm (1881 bottle finish) closure for CSD and sparkling beverages. John Greiner, CSI’s director of global 911±¬ÁĎÍř development, told Plastics Technology that CSI’s one-piece cap, the Omni mini XP, has been adopted commercially in the U.S. and Europe by the majority of its “key carbonated-beverage customers.”

Related Content

First Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

Read MoreFoam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreAt NPE, Cypet to Show Latest Achievements in Large PET Containers

Maker of one-stage ISBM machines will show off new sizes and styles of handled and stackable PET containers, including novel interlocking products.

Read MorePHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More