Aluminum Tooling Answers Hard Questions

Check your preconceptions about aluminum production tooling at Phoenix Proto’s door.

The year 2018 marked four decades in aluminum production tooling for Bob Lammon, CEO of injection molder and moldmaker Phoenix Proto Technologies, Centreville, Mich. Nonetheless, the continued skepticism his company’s core competency arouses yet today is in many ways unchanged from the late 1970s. The hardened-steel tooling crowd has same queries and assumptions.

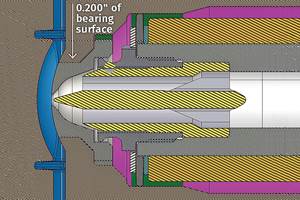

Can you hit the same tolerances in aluminum that you can in steel? Yes. Is it stable? Yes. Will it move? No. Can you do a revision in aluminum? Yes. Can you weld aluminum? Yes, it laser welds. But you can’t achieve a Class A surface finish in aluminum. Yes, you can. You can’t do side actions. Actually, you can. You can’t run 100,000 parts or 1 million shots. Yes, you can.

“I’ll take a couple briefcases of parts to show customers,” Lammon explains. “A lot of them like to touch and feel and see the parts, and they’re like, ‘Hey, that’s impressive. Did that come off of aluminum?’”

Started in 2008, Phoenix Proto works exclusively in aluminum and always has (except for one brief lapse into tool steel). It runs many of the molds it builds in-house on its seven injection molding machines, which range in clamp force from 55 to 385 tons. Tool production resides in the front of its facility, including seven CNC machining centers, three of which are high-speed with spindles running at up to 42,000 rpm. Tool making is lights out, thanks to an automated pallet system. The bulk of the 40-person staff—28 employees—work in the tooling department, building 300 to 400 molds annually. The remaining 12 staff are occupied with molding and quality. A proposed 20,000-ft2 expansion would give Phoenix room for 15 presses and expand its CNC department.

For a brief time, Phoenix Proto produced some steel tooling, before returning to its wheelhouse in aluminum—a move that pleased employees. “When we were building in steel, and I said, ‘We’re going back to 100% aluminum,’ my employees were like, ‘Yes!,’” Lammon recalls.

Part of aluminum tooling’s appeal for Phoenix Proto employees, and definitely its customers, is the enhanced pace of an aluminum tool manufacturing. “You can build an aluminum tool so much faster,” Lammon says, “and these parts that come off the tool—they look like parts that come off a hardened steel production tool.”

The speed factor derives partially from the relative ease with which aluminum can be machined compared with hardened steel. Spindle speeds and feed rates are higher with aluminum, which also allows cutting in some instances where steel would require EDM, eliminating the time and cost of making an electrode. For tools running harsher plastic materials, or to extend mold life, Phoenix Proto has some aluminum molds hard coated, working with Bales Metal Surface Solutions.

Aluminum tooling doesn’t fit every project, but the number of applications it potentially could fit is significant. “There’s a lot of project life out there that fits 100,000 parts or less,” Lammon says. “Tons of products. Is aluminum a choice for running millions and millions of shots? No—go with hardened steel. But how many companies are out there that want 5000, 25,000, 100,000 parts? Those are prefect for aluminum.”

Related Content

Design Your Tools for Moldability ... and Maintenance

In the initial design phase, when considering the structure and elements of the tool, are you designing them to be maintenance friendly? Canon Virginia has used this approach and preventive maintenance to make tool replacement a thing of the past. You can, too. Here’s how.

Read MoreHow to Achieve Simulation Success, Part 2: Material Characterization

Depending on whether or not your chosen material is in the simulation database — and sometimes even if it is — analysts will have some important choices to make and factors to be aware of. Learn them here.

Read MoreHot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.

Read MoreWhat You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More