Computer Simulation Gives Blow Molder an Edge

Spotting trouble before it starts is ingrained in the company culture at fuel-tank maker Vitec LLC.

Spotting trouble before it starts is ingrained in the company culture at fuel-tank maker Vitec LLC. This mindset has made the Detroit-based blow molder a leader in the use of computer process simulation. "I can't live without simulation because it brings so many benefits," says Karim Amellal, Vitec's product-development and engineering manager and a leading expert on blow molding simulation. "It would be unfortunate not to be able to anticipate problems before you make a part."

That view is shared throughout the organization as Vitec focuses on erasing the "black art" reputation that has dogged blow molding. Vitec, which employs 270 at its 148,000-sq-ft plant, is relatively small in fuel tanks, but jumped ahead of its competitors in using simulation. "We've been able to take a leading role because we're small and we have everyone under one roof," explains Amellal. "We validate the simulation results, going from computer to machine and machine back to the computer. By fine-tuning the prediction that way, it becomes a reliable tool."

Simulation gives the part and tool designer better understanding of material behavior during processing and helps predict part quality as a function of operating conditions, material selection, and tool design. Amellal strongly believes the software is proving valuable in accelerating development and machine set-up and minimizing mold rework. It also helps users get a tighter grip on other costs like wasted material, lost production time, and late delivery.

The beauty of simulation lies in its ability to test various "what-if" possibilities in the office, eliminating more costly trial and error on the manufacturing floor. In fact, Amellal wonders how blow molders can survive without simulation, considering today's relentless quest for cost reduction and shorter lead times, particularly in the automotive industry.

Vitec produces about one million multi-layer HDPE fuel tanks annually for GM, Daimler/Chrysler, and Harley-Davidson using BlowSim simulation software developed by the National Research Council of Canada in Boucherville, Que. Most recently, computer simulation helped Vitec assess the manufacturability of a fuel tank for Daimler/Chrysler's new Jeep model within a tight deadline. In a job for GM, simulation helped Vitec propose a weight reduction of more than 1 kg per tank, which would save GM more than $1 million/yr.

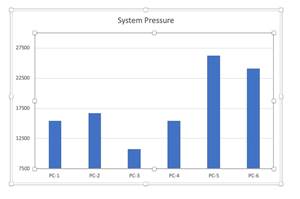

Before investing $300,000 in special die-head tooling called Programmable Wall Distribution System (PWDS), Vitec ran a simulation to predict how it would affect material distribution under different process conditions. Amellal said the simulation results gave Vitec confidence it could achieve more uniform wall thickness with PWDS, thereby permitting reduced tank weight.

How accurate is it?

Amellal estimates the accuracy of simulation at 90% to 95%. "We're getting important directions from simulation, even if it's not 100%," he says. "In the manufacturing plant you need fine-tuning to get the last 5% or so." He says the degree of accuracy hinges on building the computer model of the part with as dense a finite-element mesh as possible within the project's time constraints. "You want as much detail as you can get, but you have to choose the right number of finite elements to reduce your computation time and meet your deadline."

Up until now, the lack of user friendliness has been a prime limitation of simulation software, according to Amellal. But suppliers have rolled out more automated versions that eliminate time-consuming steps. Current simulation tools also require users to be knowledgeable about blow molding and finite-element analysis. "Most designers are not engineers, so the tool should be easy to use," suggests Amellal. Ideally, simulation should be integrated into the design software so that a manufacturing assessment takes only a click of a button.

Amellal has simple advice for blow molders considering simulation: Get buy-in from top management. Vitec is only a $150-million company, but it believes the cost of software and training is well worth the investment. Amellal dubs simulation "a one-way ticket to successful part design"—i.e., without a lot of round trips to the manufacturing floor.

Related Content

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreHow to Achieve Simulation Success, Part 2: Material Characterization

Depending on whether or not your chosen material is in the simulation database — and sometimes even if it is — analysts will have some important choices to make and factors to be aware of. Learn them here.

Read MoreScaling New Heights With Vertical Integration

Eden Manufacturing was founded on a vision of vertical integration, adding advanced injection molding capabilities to a base of precision moldmaking and more recently bringing Swiss-type machining capabilities in-house.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More