Nanolayers Enter Blow Molding

Technology mirrors Dow's recent development in blown film.

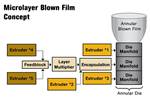

Dow Chemical Co., Midland, Mich., has adopted nanolayer technology developed for blown film (the film technology was discussed in our June issue). At the recent SPE ANTEC in Boston, a paper by Dow’s S. Crabree, J. Dooley, J. Robacki, P.C. Lee, R. Wrisley, and C. Pavlicek detailed technology that used feedblock and flow-divider technology more common in flat-die extrusion, as well as a specially configured die head to produce blow molded bottles containing more than 30 layers.

Related Content

-

Lighter, Higher Performance Base Design for Premium rPET Bottles

Sidel’s StarLITE-R Premium base for thicker rPET bottles ensures bottle stability in high-speed production, while saving energy.

-

End-to-End Quality Management For Aseptic PET Beverage Bottling

Sidel introduces Qual-IS comprehensive quality system to merge all QC activities in PET aseptic beverage bottling, from the preform blowing to laboratory management.

-

Coca-Cola’s Redesign of Small PET Bottles Pushes Lightweighting Below Prior ‘Floor’

Coca-Cola thought it had reached the limits of lightweighting for its small PET carbonated soft drink bottles. But a “complete redesign” led to a further 12% reduction.