New Look in PVC Siding

Tom Loper is a serial entrepreneur. Currently, he’s president, CEO, and co-founder of NuCedar Mills Inc. in Chicopee, Mass., which makes the first foamed PVC siding on the market.

Tom Loper is a serial entrepreneur. Currently, he’s president, CEO, and co-founder of NuCedar Mills Inc. in Chicopee, Mass., which makes the first foamed PVC siding on the market (see Learn More). Loper started out in internal consulting for large companies. He also manufactured office

supplies at Dennison Mfg. Co., helped sell office furniture at Herman Miller, and designed a high-tech call center for Lifeline Systems. Then he struck out on his own.

Loper founded NuCedar with partner Andrew Sears in 2006. It was Loper’s third venture and his second with Sears, who is president of New England Lumber Specialties in West Springfield, Mass. Three years earlier, Sears and Loper had invested in Kleer Lumber LLC in Westfield, Mass., one of the early makers of foamed PVC trim boards, which proved a strong growth market. Loper was president of Kleer, which extrudes foamed PVC sheet that is cut into trim boards.

A NEW IDEA FOR SIDING

At Kleer, Loper and Sears had the idea of milling foamed PVC sheet into siding. They figured if trim was big, siding would be even bigger, since there is four to five times more siding on a house than trim. But two other Kleer partners wanted to stick with trim boards.

Loper and Sears left to set up NuCedar and developed siding from PVC foam sheet. NuCedar uses a special “micro-milling” process to replicate beveled cedar siding. Loper explains, “We can mill at 200 ft/min. That’s much faster than we could extrude.” Dust from milling is captured and sold to local PVC sheet extruders.

Loper didn’t want to invest in extruding his own foamed sheet. But the venture-capital firm they approached for financing didn’t think there would be enough merchant capacity for foamed PVC sheet in the U.S. if foamed siding took off. U.S. producers of foamed sheet were already backlogged to meet trim-board demand.

Fortunately, Jain Irrigation Systems Ltd. in Jalgaon, India, had a sales office in Columbus, Ohio. Jain had 16 Milacron conical twin-screws and was willing to commit to support the new siding venture. Jain also wanted a controlling interest in the technology. In 2006 Jain bought 51% of NuCedar.

ANY COLOR YOU WANT

Foam isn’t the only new aspect of the upscale NuCedar siding. It’s sold pre-painted in a choice of three whites, 19 standard colors, and over 1400 custom colors. The two-part urethane paint, developed by Sherwin-Williams, is more like auto-body paint than house paint, Loper says. It contains costly solar-reflective pigments to permit the use of darker colors, reduce fading, and keep the house cool in hot weather. The product carries a lifetime warranty on coating and substrate.

Pre-finished NuCedar siding is only slightly less expensive than real painted cedar. NuCedar costs one-third more than unfinished fiber cement and at least twice as much as most PVC siding.

NuCedar started full production in February 2007, and for the first year sold siding house by house through distributors in the Northeast and Canada. Since then, distribution has expanded to the Southeast. So far, Loper says, the construction slump hasn’t hurt NuCedar. Its sales are divided about evenly between new construction and remodeling. “We’re really pleased with remodeling,” he adds. “We’re getting gorgeous multi-million-dollar homes.”

Related Content

Extrusion Excellence: This Year's Top Stories

Revisit the year’s most popular articles on extrusion technology and processes, showcasing innovations, best practices, and the trends that captured the plastics processing community’s attention.

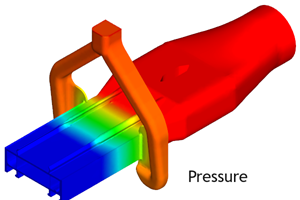

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreUpdated Software Reduces Die Design Iterations

New software said to reduce the number of fine-tuning iterations and die development time by at least 50%.

Read MoreHow to Effectively Reduce Costs with Smart Auxiliaries Technology

As drying, blending and conveying technologies grow more sophisticated, they offer processors great opportunities to reduce cost through better energy efficiency, smaller equipment footprints, reduced scrap and quicker changeovers. Increased throughput and better utilization of primary processing equipment and manpower are the results.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More