Novel Two-Stage Approach Makes Purging Hot Runners a Breeze

Two new and unusual compounds have been developed to ease the challenge of purging injection molding hot-runner systems.

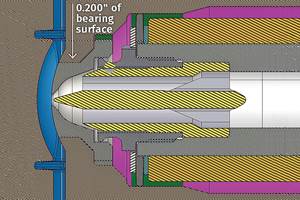

Two new and unusual compounds have been developed to ease the challenge of purging injection molding hot-runner systems. The long residence time of melt in these systems often leads to troublesome deposits of degraded material. These deposits can be hard to dislodge and tend to shed black specks.

One of the new compounds is used at start-up ofa new resin or color. It coats the melt channel, forming a barrier that insulates the resin being molded from excessive heat exposure. It is easy to purge from the system, so it acts more like a release coating for the resin being molded than an actual purging agent.

The other new product is a purging agent that acts by a novel process of “molecular cavitation,” which is said to clean the screw and hot runner safely and more effectively than standard purging materials.

These products are sold under the Cel-Span brand name by Phoenix Plastics, a custom compounder and supplier of specialty additive masterbatches. They were co-developed together with Stabilization Technologies, a consulting firm in Charlotte, N.C, headed by Joseph R. Webster, a well-known expert in additive chemistry for plastics and fibers. According to Webster, such a two-pronged approach provides the best control of black specks and cross-contamination between materials and colors in molded parts.

Both products are typically offered in non-wax polyolefin carriers for resins processed in the 350 to 575 F range, including polyolefins, styrenics, TPOs, TPEs, and TPUs. Custom carriers are offered for other materials, such as glass-filled nylon.

Release coating & heat barrier

Webster describes Cel-Span 310 as an “interfacial resin barrier compound” that is designed for use at start-up to protect the plastic from thermal-oxidative breakdown in hot-runner channels. Containing a proprietary stabilizer system, it functions as a durable release coating that builds up into a heat-stable barrier between the tooling metal and the plastic being molded. Says Webster, “Starting up with 310 after a major hot-runner mold cleanup will establish a thermally stable cap and coat the metal with a heat-stable polymer. It is the key to extended stabilization and prevention of black specks and crossover contamination.”

When it comes time to change colors or resins, Cel-Span 310 is easily expelled with a purging compound, such as Webster’s other new product.

Novel transition purge

Cel-Span 399 transition purging compound functions as both a chemical and physical purging agent in hot-runner systems with frequent resin or color changes. It contains a proprietary inorganic, non-abrasive, nitrogen-based chemical foaming agent. It is non-acidic and non-corrosive and produces no acidic byproducts that can interact with the mold or materials being molded. As with other chemical purging agents, it also contains detergents and a thermal-oxidative stabilizer system.

Although initiated by chemical foaming, the compound’s physical purging action is accomplished by microscopic gas bubbles. The bubbles expand and condense into a liquid that solvates and softens de-graded resins and remnants of the previous color or material. In what Webster calls molecular cavitation, the bubbles expand and contract and work their way under degraded material that has adhered to the screw and/or hot runner.

“When the cavitation is at its best, the cycle of gas to liquid to gas is resonant and acts to remove by solvation all remnants of the material on the screw and hot-runner wall. This physical purging action, in combination with the chemical action of the other ingredients, prevents viscosity drop while maintaining the oxidative integrity of the plastic over time,” says Webster.

Related Content

Construction Begins on Fully Automated Hot Runner Production Plant

Oerlikon HRSflow will start the construction of a new fully automated plant in San Polo di Piave, Italy, to expand capacity for the growing European market.

Read MoreHot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MorePlate Design for Synchronous Valve Pin Movement

Heitec’s type 64.086 Syncro Plate for valve-gate systems, which is distributed in North America by Technoject Machinery, enables fully synchronous motion with valve-pin positioning accuracy down to 0.01 mm.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More