Nozzle Shutoff Shuts Down Drool

A machine-nozzle shutoff device helped Klein Tools cut drool from 24 lb/day to just 2.1 lb, with the remaining drool coming from the hot runner, not the machine.

When nozzle drool forces production pauses every couple hours and is measured in dozens of pounds a day, it has reached an unsustainable level. Klein Tools Inc. in Lincolnshire, Ill., a family-owned maker of premium hand tools, came to that realization when its vertical overmolding cells, which produce polycarbonate screwdriver handles with a soft-touch grip, began drooling to the tune of 7 to 10 lb after each shift. In addition to representing a waste of resin, the drool would collect and harden among the molding machine’s water lines, leading to leaks, damage and more downtime.

Polycarbonate drool at Klein Tool’s screwdriver overmolding cell accumulated in amounts that required production interruptions until the company switched to a Melt Design nozzle.

At Klein Tools’ production facility in Mansfield, Texas, each of the three screwdriver cells contains two vertical molding machines and a transfer system in which screwdriver handles are molded out of polycarbonate in the first machine and then overmolded with a softer cushion grip material in the second machine.

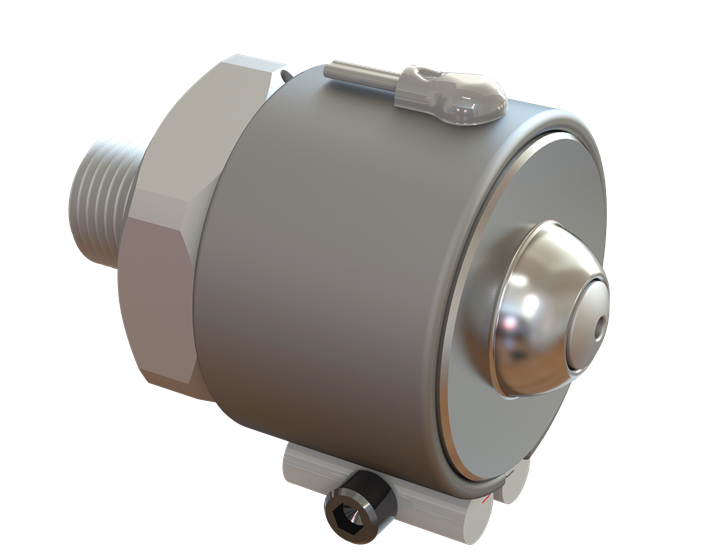

After some research, Jason Burcicki, manufacturing engineer at the Mansfield plant, settled on Melt Design Inc.’s Machine Nozzle Shut-Off device. Melt Design manufactured its shutoff device to be installed on the molding machine nozzle, giving processors added control of the flow of material into the mold and greatly reducing any drool.

Melt Design says this is especially applicable to insert molding, where the nozzle must back away from the hot-runner intake in each cycle. The company initially developed the concept behind the device to resolve issues a customer was having with a stack mold. Melt Design applied knowledge gained from that project—the patented Anti-Drool Sprue Bar Device—for this new device. The Anti-Drool Sprue Bar device stops material flow and prevents leakage from the sprue bar.

Klein Tools set a goal of reducing drool by 25%, but since the Melt Design device was installed in early April, the company has seen drool drop to less than 1 lb/shift, or better than 90%. Klein notes that the only material drool it still sees comes from the hot-runner side, not the machine nozzle. The device has also meant that Klein Tools’ molding technicians no longer must stop production every hour or two to clean out the drool, waiting instead until the end of each 8-hr shift. Ultimately, Klein Tools went from losing an average of 24 lb of drool per day at a cost of $2171.52 per month to losing only about 2.1 lb of drool per day at a cost of only $190.01 per month.

“Right away we noticed that there would be less scrap and less purge coming out of the nozzle,” Burcicki says. “Polycarbonate was the biggest hitter financially on our list of material scrap.” Because of the success with the first Machine Nozzle Shut-Off device, Klein added two more in May and June to outfit the other two screwdriver cells. “The financial impact of adding these nozzles was high,” Burcicki says, “and I am glad that we decided to try this method out.”

Melt Design Inc.’s Machine Nozzle Shut-Off device helped Klein Tool eliminate machine-related drool issues.

Related Content

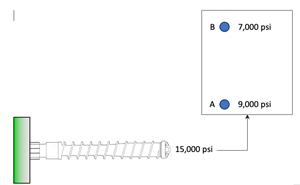

Understanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

Read MoreIs There a More Accurate Means to Calculate Tonnage?

Molders have long used the projected area of the parts and runner to guesstimate how much tonnage is required to mold a part without flash, but there’s a more precise methodology.

Read MoreUse These 7 Parameters to Unravel the Melt Temperature Mystery

Despite its integral role in a stable process and consistent parts, true melt temperature in injection molding can be an enigma. Learning more about these seven parameters may help you solve the puzzle.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreRead Next

INJECTION MOLDING: The Trouble with Mismatched Nozzle Tips & Sprue Bushings

It happens more than most molders realize and can cause a host of molding problems. Here’s what to look for and how to fix it.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More