Pushing the Limits Of Structural-Web Molding

Four years of development and over $7.5 million have resulted in what is believed to be the largest part ever made by gas-assist injection molding and also the largest ever made by the structural-web process, a variant of gas assist.

Four years of development and over $7.5 million have resulted in what is believed to be the largest part ever made by gas-assist injection molding and also the largest ever made by the structural-web process, a variant of gas assist. This 75-lb polypropylene part is a section of a stormwater chamber from Stormtech LLC in Weathersfield, Conn. Measuring 50 in. wide, 30 in. high, and 7 ft long, the thin-walled chamber imposed molding challenges that required a new type of 2000-ton structural-web machine from Uniloy Milacron, Manchester, Mich., which owns the structural-web patents.

Stormtech is a new 50/50 joint venture formed last July by Infiltrator Systems Inc. (ISI) of Old Saybrook, Conn., and Advanced Drainage Systems, Inc. (ADS) of Hilliard, Ohio, to engineer and manufacture chambers for underground stormwater detention and retention systems. ISI is reportedly the leading producer of polyolefin septic chambers and subsurface stormwater chambers, while ADS is said to be the leader in corrugated HDPE pipe for stormwater systems.

ISI has been one of the largest users of structural-web technology for 12 years and is the only molder in the world fully dedicated to this process. The technology itself is used by a very small number of molders. But in the last three years, interest has picked up considerably. “About 50% of the low-pressure machines we are currently selling are being used for structural web,” says Ed Hunerberg, executive director of structural-foam 911±¬ÁĎÍř at Uniloy Milacron.

Stormtech’s new stormwater chamber pushes the envelope of this technology to a new level. ISI uses Uniloy Milacron machines from 1500 to 2500 tons for structural web, but Stormtech’s new 2000-ton machine differs from past models in that it has 110 x 107 in. platens with 2.5 times more clamp tonnage per square inch than previous machines. Before the Stormtech chamber, the largest structural-web chamber molded by ISI weighed 35 lb, according to Roy Moore, v.p. of manufacturing at ISI, which molds products for Stormtech. Molding a larger part with thin walls required a machine with a beefier clamp. It also has an 8-in. extruder with 30:1 L/D and 1000-hp, variable-frequency AC drive instead of the usual 6-in., 600-hp, DC-drive extruder. This gives it larger shot capacity (160 lb) and higher plasticating rate (6000 lb/hr) than any previous structural-web machine.

Structural web vs. foam

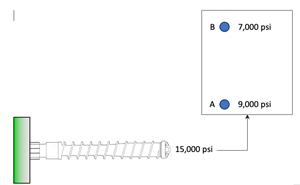

Uniloy Milacron’s structural-web technology is a short-shot process that creates controlled internal hollow channels in parts that increase stiffness and strength while saving material and cycle time. It can be performed on the same multi-nozzle, low-pressure injection machines that Uniloy Milacron builds for structural foam. The difference is that for foam, nitrogen gas is injected into the extruder barrel and mixed into the melt to produce a part with a solid skin and cellular core. For structural web, the nitrogen gas is injected through special polymer/gas nozzles directly into the mold. The result is a solid skin with hollow thick sections such as structural ribs. Mold cavity pressure is only 400 to 600 psi, as compared with 2000 to 4000 psi for gas assist.

Moore says the web process produces a much smoother surface finish than structural foam. More important, it produces thinner parts in much faster cycles. According to Moore, a structural-foam machine (used by competing makers of septic chambers) typically produces a 0.250-in. wall in a 2.5- to 3-min cycle, while structural-web molding on the new 2000-ton machine creates walls 0.188-in. thick in half or two-thirds the cycle time for foam. That’s because the web structure cools faster than foam, Hunerberg explains. “In general, a thin-wall structural-web part also weighs 10% to 25% less than a structural-foam part,” adds Moore. Structural-web parts are also said to be stronger and stiffer.

Moore says Stormtech’s PP stormwater chambers weigh less and have better resistance to heat and ESCR than competing vacuum-formed HDPE chambers. He adds that low-pressure structural-web molding beats thermoforming in control of wall thickness and accurate fit of end caps and joints. It also imparts lower internal stresses and only one heat history to the part. Another advantage is improved design flexibility, which enables thin wall sections with thick hollow ribs.

Related Content

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreUnderstanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

Read MoreGot Streaks or Black Specs? Here’s How to Find and Fix Them

Determining the source of streaking or contamination in your molded parts is a critical step in perfecting your purging procedures ultimately saving you time and money.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More