What Output Can I Expect?

Processors ask screw designers this question a lot. But neither output nor melt temperature can be predicted without details on the polymer and head pressure.

An extruder screw is not a complete system in itself. It’s just one component that interacts with the extruder design, the rheology and tribology of the polymer, and the head pressure. You can’t predict the output and melt temperature of a given screw design without all of this information. For a given screw design and extruder, the output and melt temperature are strongly affected by polymer characteristics and head pressure. As a result such “predictions” are often inaccurate and have to be treated as an educated guess at best.

With Newtonian fluids such as oil, water, or syrup, which have a fixed viscosity at a specific temperature, the pressure drop through the tooling is directly proportional to the output under isothermal conditions. In other words, double the output and expect the head pressure to be doubled. This is called the die characteristic and is described as follows:

Q = K Dp/μ, where:

Q = Output, Dp=Pressure drop through the die

μ=Viscosity of fluid

K=Die characteristic

However, this does not apply to polymers that have non- Newtonian behavior or shear thinning with increasing shear rates and temperature. The polymer viscosity (μ) is therefore a variable based on the shear rates and temperature through the die at the desired output and must be determined from shear rate/viscosity data on that polymer to predict the head pressure.

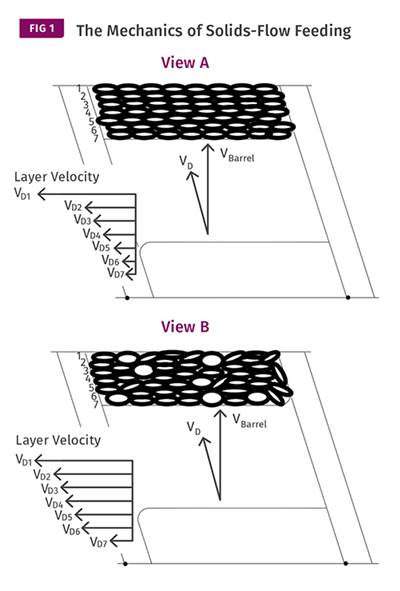

As Fig. 1 shows, the shear-thinning effect is different for every polymer and grade. Further, the individual curves are offset up or down as the temperature decreases or increases, respectively. The effect shear rate and temperature have on polymer viscosity in the tooling can result in considerable variations in pressure drop through the die.

Die-flow calculations are quite complex due to the many different shear rates and flow variations that occur in most dies. A similar effect occurs in the screw, as its pumping capability is also related to the shear rate, temperature, and resulting polymer viscosity. The screw characteristic is determined by the difference between the drag flow and pressure flow. The pressure-flow calculation depends on the viscosity in the screw channels. Because the calculations are quite different in the tooling and the screw, there is no parallel path to calculate the net effect, even if the two viscosities were identical. Each one must be dealt with individually.

Since at both ends of the extrusion process the pressure is atmospheric, the pressure buildup through the screw has to equal the pressure drop through the tooling to achieve a balanced system. The screw and tooling therefore interact to determine the actual output. As the pressure drop changes to push polymer through the tooling, the specific output (lb/hr-rev) of the screw is affected in the opposite way by pressure flow in the screw. Pressure flow is a loss of output due to increasing head pressure. What occurs is a sort of induced reverse flow in the screw—or a recirculation of the flow in the screw’s pumping section— much like closing a valve on any fluid pump (and a screw is a spiral pump). The higher the tooling pressure drop, the lower the screw output at a specific screw speed—and conversely for lower die pressure.

This interaction between the screw and tooling creates the balance or “operating” point between pressure drop through the tooling and the screw output. Every extrusion system has an operating point, and it can only be calculated by knowing the tooling pressure drop and the resulting pressure flow in the screw.

A further complication occurs when the specific output of the screw is reduced by increasing head pressure. In the case of higher head pressure, the specific energy going into the polymer is increased, thereby increasing melt temperature. The increased melt temperature means further reduced viscosity of the polymer and more pressure flow in the screw but less pressure drop through the tooling. It’s a moving target, and to estimate the system’s output you need knowledge of the polymer viscosity, the screw performance, and the die characteristic.

Combining the die and the screw characteristics will determine the operating point. The operating point will be higher for a low-pressure die than for a high-pressure die with the same screw design and polymer (see Fig. 2).

The point is that predictions of extruder output based solely on screw design cannot be made with any degree of accuracy without specific head-pressure and polymer data. There are too many estimates involved without that data to consider them accurate calculations. The more data available, the more accurate the estimates.

In the real world, however, sometimes estimates must be made when planning a new system. That usually involves estimates of the effect of viscosity in the screw and tooling based on similar polymers, along with estimates of the die pressure drop based on the same extrudate cross section compared with the planned output rate. Keep in mind how many estimates or even guesses are involved before putting too much faith into this data.

ABOUT THE AUTHOR: Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 40 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724)651-9196.

Related Content

Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreGot Streaks or Black Specs? Here’s How to Find and Fix Them

Determining the source of streaking or contamination in your molded parts is a critical step in perfecting your purging procedures ultimately saving you time and money.

Read MoreFundamentals of Polyethylene – Part 6: PE Performance

Don’t assume you know everything there is to know about PE because it’s been around so long. Here is yet another example of how the performance of PE is influenced by molecular weight and density.

Read MoreWhat to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.

Read MoreRead Next

Extruding Very High-Flow Polymers

Screw designs not suited to process lower-viscosity materials will result in poor melt quality and lower outputs.

Read MoreEXTRUSION: Pellet Geometry Can Impact Output

A simple angle-of-repose experiment can help you determine how your pellets will feed.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More.jpg;width=70;height=70;mode=crop)