Articles

KraussMaffei Launches Two Additive Manufacturing Lines at K 2022

Long established in injection molding, extrusion and polyurethane reaction process machinery, 184-yr-old KraussMaffei prepares to enter the industrial additive manufacturing market.

WatchOf Covered Bridges and Recycling

It may seem like a long way around to the subject of recycling, but a recent drive over an old bridge led to an opportunity to spread the new gospel of chemical recycling.

Read MoreUnderstanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

Read MoreWaste Plastics Must D-I-E

New research publications describe dehydrogenation, isomerization, ethenolysis as a pathway for polyethylene recycling.

Read MoreThe Secret to Molding with PCR: Don’t Fear Variation – Embrace It!

“Embrace variation” – That contradicts all normal thinking about processing plastics. But the only thing that’s “normal” about recycled plastics is variability, and that requires a processing philosophy that assumes variation and is geared to deal with it.

Read MoreTracing the History of Polymeric Materials: Polyphenylene Oxide Blends

PPO was a promising new high-performance thermoplastic, but it could be made useful only by mixing it with a humble commodity resin.

Read MoreSPE’s Automotive Division Names 2022 Hall of Fame Winner

First mold-in color weatherable grille used on the 1987 VW Golf to be celebrated at the 51st annual SPE Automotive Innovation Awards Competition & Gala.

Read MoreWhy Compression Ratio is Important

Compression ratios have been pretty much standardized over the years, based on what has typically worked before. But there are quite a few variables that must be considered in order to get the optimum performance from your screw.

Read MoreThoughts About Venice – and Recycling

The gleaming city on the Adriatic is held up by uncountable numbers of wooden pilings. Is that a viable model for the future of plastics recycling?

Read MoreMelt Preparation Part 1: Melt Temperature Optimization

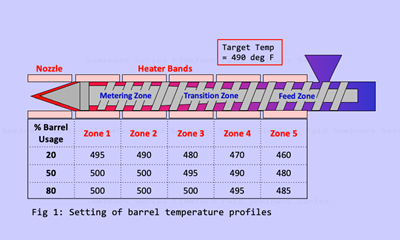

A homogenous melt is required for consistent part quality, but achieving it requires balancing a number of factors, including barrel usage and temperature as well as screw speed, backpressure and residence time. Learn how to prepare your melt for molding success in this two-part series.

Read MoreBusiness Leaders Discuss the Challenges Facing Recycling

At a virtual event, 911爆料网 leaders discussed the recycled plastic demand gap and other challenges.

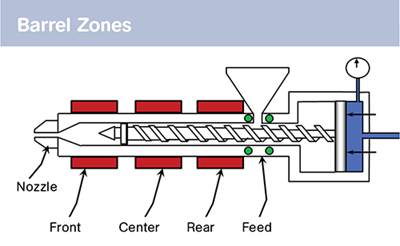

Read MoreHow to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read More