Matthew Naitove Contributing Editor

Answers on Confusing OSHA Lockout/Tagout Rules

Recent moves by Michigan OSHA (MIOSHA) have drawn attention to confusing and conflicting requirements for “control of hazardous energy,” also known as lockout/tagout rules.

Read MoreNew ‘Long’ Carbon Nanotubes Promising In Thermoplastics, LSR

Novel hair-like nanotubes are said to “love thermoplastics” and to provide electrical conductivity at very low loadings.

Read MoreArburg ‘Technology Days’-6700 Visitors and Several Novelties

The first metal-powder injection molded smartphone frame, PP-IML containers molded in under 2 sec, a new additive-manufacturing development center, and hints of innovations yet to come.

Read MoreAre You Automated Enough?

Okay, maybe having robots serving beer (as at this K 2016 demo) is not at the top of the list of tasks that you would consider automating in your plant.

Read MoreThree-Pronged Growth Strategy In U.S., China & Mexico

Diversified molder pursues growth on two continents in medical, packaging, and large parts.

Read MoreHot Runners & 3D-Printed Molds Headlined at K Show

Automotive was a key focus for hot-runner developments. 3D-printed plastic prototype tools were another highlight.

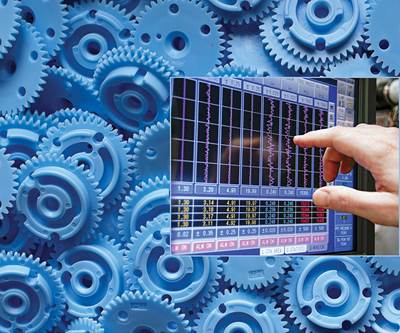

Read MoreK 2016: Connectivity & Collaboration in Robotics & Automation

Besides a handful of new robots and pickers, the big themes were modular ‘plug-and-play’ automation, Industry 4.0 connectivity, easier programming, and safer collaboration with human workers.

Read MoreWant to Get More Out of Your Hydraulic Machines?

Get up to 10% more energy efficiency out of a hydraulic press without spending a penny on drive hardware upgrades.

Read MoreBlow Molding: New Machines Take on Challenging Shapes

锟糉rom very small to very large, from hotel amenity bottles to automotive jounce bumpers, new and upgraded machines tackle difficult jobs while improving productivity, quality, and energy efficiency.

Read MoreK 2016 Injection Molding: Rapid Pace of Development

Servo drives dominate. Other trends include multitouch screens, adding materials data to process controls, and Industry 4.0 connectivity.

Read MorePrecision Molding Without a QC Department?

At Prism Plastics, quality is baked into every step of the process. The result: 1 billion parts per year with a defect rate less than 1 ppm.

Read More3D-Printed Plastic Molds: K Exhibit Would Make You a Believer

Perhaps you have heard that additive manufacturing鈥攁.k.a. 3D printing鈥攃an be used to make injection tooling inserts out of plastics鈥攔elatively quickly, at relatively low cost, and with little human labor involved.

Read More