3D Printing Helps Niche Manufacturer Bring Product to Market

PT sister publication Additive Manufacturing showcases an interesting example of a unique product manufactured via 3D printing.

One of the many exciting benefits of additive manufacturing is the ability for niche manufacturers to offer low-volume production that is both flexible and cost-effective. For instance, our sister publication Additive Manufacturing recently featured the Periscope Case, which is produced via 3D printing with no investment in tooling. In addition, the production quantity can be scaled to the market size.

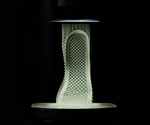

Marketed as the “poor man’s GoPro,” the Periscope Case converts smartphones into an action camera. The case is manufactured for the startup Defox LLC on ’s 3D printing platform by RapidMade of Tigard, Oregon.

Check out the below video from Additive Manufacturing’s Pete Zelinski where he showcases the product. Learn much more in his .

explores how manufacturers are applying 3D printing to make tooling, molds, functional prototypes and end-use parts. .

Related Content

-

3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

-

The Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.

-

KraussMaffei Nears Completion of Corporate Headquarters Move

The 185-yr old German maker of plastics processing machinery is shifting to a more than 200,000-m2 greenfield site in Parsdorf.