Custom Molder Gets More Mileage From 3D Printer

Use of 3D printer to save time and money in new ways is satisfying to custom molder.

Getting even more out of its investment of bringing 3D printing design capabilities in-house a couple of years ago in order to produce 3D fit-form-function prototypes that can be verified before making a costly steel mold is very satisfying to a custom injection molder and blow molder, primarily of packaging, as well as amenities, household consumables, electronic connectors, and medical-measuring devices.

Since its acquisition of an Objet 30 3D printer from Stratasys, which allows it to use photopolymers that simulate ABS and PP, the company has printed approximately 425 bottles, jars, canisters, closures, and lids, and continues to find new uses for this additive manufacturing technology.

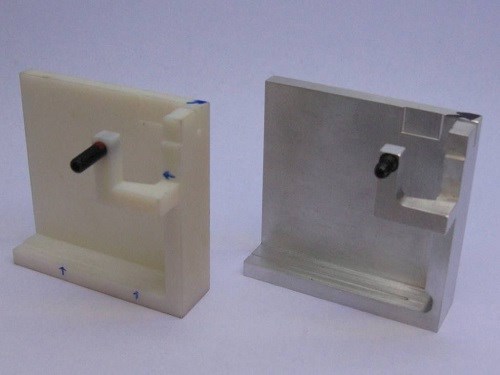

Says v.p. of new product development Gary Kieffer, “Lately, we’ve had a few occasions where we’ve utilized the 3D printer for jobs other than product development. First, our design and QA teams, collaborated to make a Geometric Dimensioning & Tolerancing (GD&T)—a holding fixture for a new custom bottle we designed. This fixture will help to simplify part inspection and would normally have cost at least $1200 to manufacture. Then, our automation engineer was working on a modification of a cap-closing station. The vendor sent in the base plate and flipper bar models and we printed them overnight and validated the redesign, saving not only cost but also shaving about two weeks off the unit tools lead-time. As we experiment more and more, our team is finding out that our 3D printer is worth its weight in gold.”

Related Content

-

Coca-Cola’s Redesign of Small PET Bottles Pushes Lightweighting Below Prior ‘Floor’

Coca-Cola thought it had reached the limits of lightweighting for its small PET carbonated soft drink bottles. But a “complete redesign” led to a further 12% reduction.

-

First Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

-

Breaking the Barrier: An Emerging Force in 9-Layer Film Packaging

Hamilton Plastics taps into its 30-plus years of know-how in high-barrier films by bringing novel, custom-engineered, nine-layer structures resulting from the investment in two new lines.