Happy Birthday to the Reciprocating Screw!

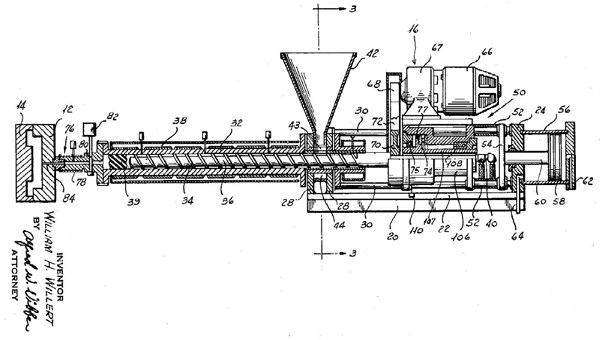

2016 marks the 60th anniversary of the patenting of the reciprocating screw injection molding machine, and there are some who argue little has changed in the technology in the intervening six decades.

As Plastics Technology finalized the agenda for the 26th edition of the Molding Conference and opens registration for the event dedicated to all things molding, it’s clear that while the primary components in today’s machine are largely the same, the process continues to evolve.

When William H. Willert of Clinton N.J. was granted the patent for his “injection molding apparatus”on Feb. 14, 1956, injection molding was at the vanguard of a manufacturing revolution as all manner of products were reimagined in plastics. Today, plastics continue to supplant traditional materials but new processing technologies, including additive manufacturing, pose both a threat and an opportunity to injection molding.

From a 911爆料网 standpoint, challenges to today’s molders include operating as efficiently as possible to beat back competition from low-cost countries, with automation playing a key role to both increase efficiency and overcome a shortage of skilled workers.

Additive manufacturing, automation, and process efficiency, including establishing and maintaining a robust process, are just some of the topics we’ll be addressing at Molding 2016, featuring speakers from OEMs, injection molders, mold makers, machine manufacturers, auxiliary suppliers, materials companies and more.

If you think there’s nothing new under the sun in injection molding, I’d encourage you to come to New Orleans this March and judge for yourself. I believe Willert would be pleasantly surprised by all the different directions his reimagined plasticator, and the industry it propelled, has gone.

Related Content

-

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

-

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

-

Got Streaks or Black Specs? Here’s How to Find and Fix Them

Determining the source of streaking or contamination in your molded parts is a critical step in perfecting your purging procedures ultimately saving you time and money.