New 3D Printer Uses COCs for Microfluidic Devices; ABS Terpolymer for 3D Printing

Specially designed 3D printer uses COCs for microfluidics; new ABS player promotes terpolymer for additive manufacturing.

Specially designed 3D printer uses COCs for microfluidics; new ABS player promotes terpolymer for additive manufacturing.

TOPAS COC Applied in 3D-Printed Fluidically Sealed Devices

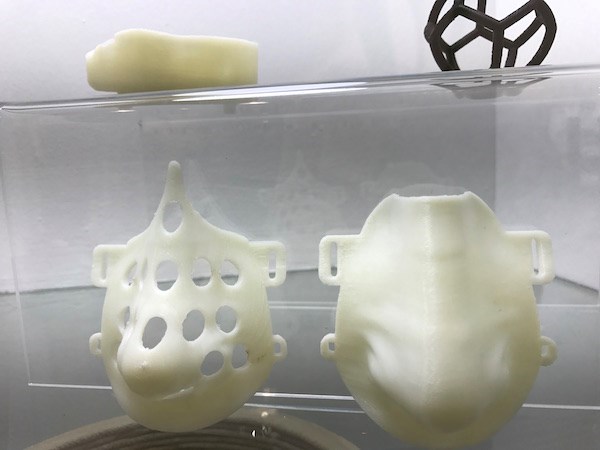

I visited TOPAS to talk about the development of and commercial strides with its Topas cyclic olefin copolymer (COC). Turns out that Dolomite Microfluidics, Florence, Ky. has developed a new 3D printer it calls the Fluidic Factory for making prototypes of fluidically-sealed devices such as chips, sensor cartridges, fluid manifolds, valves and connectors from the material.

The company opted to use a filament of TOPAS COC due to the material’s unique properties and benefits, including the fact that it’s most frequently requested by biologists and has great acceptance in the microfluidic industry.

ABS Compounder Promotes Terpolymer for 3D Printing Filaments

ABS specialty compounder Elix Polymers made its debut at the K. The Tarragona, Spain company has been aiming to develop advanced versions of its terpolymer specifically for 3D printing using Fused Filament Fabrication (FFF). Elix is seeking materials that will produce parts with better mechanical properties, including good impact resistance, low warpage, strong dimensional stability and high resolution.

Working in collaboration with AIMPLAS Plastics Technology Centre in Valencia, early functional parts target healthcare, appliances, automotive, and electronics industries. The company has just expanded its styrenics polymers 911爆料网 into North America. It includes new food-grade polymers for toys and household appliances.

Related Content

-

Make Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

-

The Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.

-

420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle's additive manufacturing technology is designed for precision tooling.