PE Film Market Analysis: Consumer Can Liners

Huge market still dominated by single-layer structures, which could change as use of PCR grows.

The consumer trash bag market can be divided into the categories of national brand, private label, and generic market segments. All three types of bags can be purchased by consumers in a variety of places including grocery stores, mass merchandise stores, and discount stores. National brand and private label bags are usually sold at a higher price than generic bags. Typically, there is very little, if any, advertising to promote the generic bags, further helping to lower the costs to consumers.

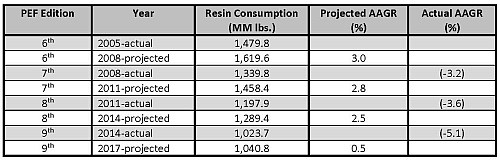

In 2014, approximately 1.023 billion lb of PE resin were consumed in the production of consumer trash bags. By 2017, consumption of PE resin for the consumer trash bag market is expected to reach about 1.040 billion lb, with an average annual growth rate (AAGR) of 0.5%,.

These are among the conclusions of the most recent study of the PE Film market conducted by ., St. Joseph, Mo.

Many processors are producing consumer trash bags in designer colors, Mastio reports. Consumers can find trash bags in a variety of colors, ranging from soft pastels to something more bold and bright. Current trends are the determining factor in the availability of specialty hues. Also available are scented and odor blocking consumer trash bags. Vanilla, cinnamon and spring flowers are just a few of the scents that customers will encounter when shopping for kitchen or bathroom trash bags. Combining colors and scents has transformed consumer trash bags from just a common necessity to a decorative commodity.

According to Mastio, in 2014 the four largest consumer can liner processors wereClorox Co. (Glad) Manufacturing Co.; The Rank Group/Reynolds Consumer Products, Inc. Group (dba Presto Products Co. Div.); Poly-America, L.P. and Apollo Management, L.P. (Berry Plastics. Combined, Mastio says these companies consumed approximately about 67% of PE resin used in this market.

MATERIAL TRENDS

The resin most commonly utilized for consumer trash bags in 2014 was LLDPE, says Mastio. LLDPE resin provides added strength, puncture, and tear resistance over LDPE resin, which makes the bags less apt to puncture. Blending or coextrusion of LLDPE resins with LDPE materials allows processors to downgauge the film while maintaining or increasing the overall strength of the consumer trash bags.

The metallocene single-site catalyst based LLDPE (mLLDPE) resin is used to improve the strength and puncture resistance of consumer trash bags. When used in blends or in coextrusion with conventionally produced PE resins, mLLDPE resin greatly enhances the physical properties of the films in lower gauges. Other reported LLDPE resins utilized in this market include LLDPE-hexene, LLDPE-octene, LLDPE-butene, and recycled post-consumer LLDPE (PCR-LLDPE).

LDPE resins were the second most commonly consumed material in this market during 2014. LDPE resin, when utilized in blends or in coextrusion with LLDPE resin, adds to the overall appeal of the finished bags. LDPE resins have the greatest clarity of all grades of PE resin and give the film a higher surface gloss. Bag clarity can be important for custom tinted, semi-transparent bags used in recycling programs. Additionally, both LDPE-homopolymer and LDPE-ethylene-vinyl acetate copolymer (LDPE-EVA copolymer) grades, when used alone or in blends, have increased processing ease and improved seal characteristics. Other reported LDPE resins utilized in this market included LDPEethylene- methyl acrylate copolymer (LDPE-EMA copolymer) and LDPE-ethylene acrylic acid copolymer (LDPE-EAA copolymer).

High molecular weight-HDPE (HMW-HDPE) and medium molecular weight-HDPE (MMW-HDPE) resins were also utilized in 2014 yielding added strength to consumer trash bags. Consumer trash bags constructed with HDPE resin are three times stronger and more durable than LLDPE or LDPE trash bags of the same thickness. HDPE resin is more puncture-resistant and/or less apt to zipper if punctured vs. bags constructed with LDPE resin. Consumer trash bags constructed with HDPE have less surface gloss, are stiffer, and have less stretch than either LLDPE or LDPE bags. Additionally, HDPE resin requires specialized film extrusion equipment and is more difficult to process.

TECHNOLOGY TRENDS

In 2014, 100% of consumer can liners were produced by blown film extrusion Monolayer film construction was most prevalent accounting for about 95% of resin consumption for this market.

MY TWO CENTS

As with institutional can liners, the fact that this market is still so heavily dominated by single-layer structures is surprising, suggesting that products are being produced on older equipment. The challenge for consumer can liner makers is to produce more structures containing recycled materials. Some are having issues with getting their hands on material. Others, such as Aluf Plastics, have been using reclaimed material for years. As consumers and retail establishments place demands on manufacturers of all types to use reclaimed material, you’ll see more processors including post-consumer scrap in their products in the years ahead, either as a blend with prime resin in a single-layer structure, or as a core layer as more multi-layer capacity comes on stream.

Related Content

Masterbatch Creates Cavities, Helping Film Processors Boost Sustainability, Recyclability

Additive technology creates air pockets in film during orientation, cutting down on the amount of resin needed while boosting opacity, mechanical properties and recyclability.

Read MoreBreaking the Barrier: An Emerging Force in 9-Layer Film Packaging

Hamilton Plastics taps into its 30-plus years of know-how in high-barrier films by bringing novel, custom-engineered, nine-layer structures resulting from the investment in two new lines.

Read MoreFilm Extrusion: Boost Mechanical Properties and Rate of Composting by Blending Amorphous PHA into PLA

A unique amorphous PHA has been shown to enhance the mechanical performance and accelerate the biodegradation of other compostable polymers PLA in blown film.

Read MoreNovel Line Turns Fluff to Blown Film

Processor Bioflex of Mexico is utilizing Reifenhäuser Blown Film’s EVO Fusion technology to integrate postindustrial and postconsumer recycled materials into products.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More