Prove Your Molding Mettle

Multiple injection molders have put their parts forward to win the first-ever Hot Shots Injection Molded part competition—enter your most unmoldable part to prove your plastics prowess.

In addition to exhibits, presentations and collocating with two other leading plastics processing events— and — will also feature for the first time a parts competition: . All attendees will be eligible to vote on which part they feel best satisfies the contest’s criteria, including technical sophistication or efficiency gains, either in the molding process or economically.

Maybe you helped convert a machined metal component to a molded plastic or found a way to utilize recycled resin for an application where such resins had previously been verboten. Perhaps on your floor right now, you’re running a part that consolidated disparate materials and processes into a single injection molded component, or maybe, you helped redesign a product so that it is ejected from your mold ready for use, eliminating secondary operations.

Show off your molding chops and enter the competition today. Let your current (and potential future customer) know what your injection molding facility is capable of.

Submit your part today for consideration and be a part of the first-ever Hot Shots part competition.

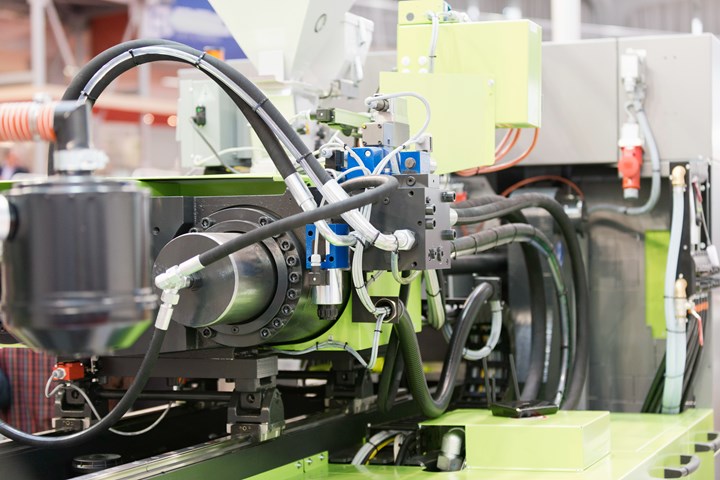

Are your machines running parts today that could get you recognition at Molding 2021?

Related Content

-

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

-

Is There a More Accurate Means to Calculate Tonnage?

Molders have long used the projected area of the parts and runner to guesstimate how much tonnage is required to mold a part without flash, but there’s a more precise methodology.

-

Got Streaks or Black Specs? Here’s How to Find and Fix Them

Determining the source of streaking or contamination in your molded parts is a critical step in perfecting your purging procedures ultimately saving you time and money.