Teaching Kids About the ‘Magic’ of Manufacturing

Making something out of (almost) nothing is an ‘eye opener’ for youngsters in their first exposure to plastics processing.

How does a bunch of plastic pellets get transformed into a product such as a swimming-pool ladder? That’s the practical “magic” of manufacturing that engages young people who visit Confer Plastics’ blow molding plant for the first time. (Photo: Confer Plastics)

Something struck me while I was interviewing the head of a blow molding company for the upcoming On-Site feature in the April issue of Plastics Technology. Bob Confer, president of family owned Confer Plastics in North Tonawanda, N.Y., was telling me about the perennial shortage of available labor, made worse by declining school enrollments in New York State. Confer Plastics, he said, was lucky in having nearly a quarter of its employees in the “20-year club” – indicating their lengthy tenure at the company. But Confer Plastics still has the challenge of finding new employees to make up for attrition and support growth (the company has added its 20th accumulator-head machine).

To attract young people to jobs at Confer Plastics, as part of the firm’s community outreach program, the company sponsors open houses and offers internships and “shadowing” programs through which high-school juniors and seniors spend a day with an employee to learn about manufacturing careers. The company welcomes visitors from community organizations and students from local high schools, elementary schools and colleges. “It’s an eye-opener for them,” Bob Confer says, “to see tiny beads of plastic transformed into all these parts.”

That last bit made me stop and think. I’ve heard other molders tell me how they hoped a profusion of glowing touchscreens throughout their plants would convince today’s smartphone-dependent teenagers that “this isn’t your grandfather’s sooty old factory.”

I had nodded approvingly at such remarks in past interviews. But Bob Confer’s comment showed me a new angle on the matter. There might be something less than optimal about hiring kids who look forward to poking touchscreens or keyboards all day long, if they don’t have a real feeling and a real concern for what’s physically happening inside the machine that is reflected in those blinking screens.

How much more valuable might those new recruits be if they were captivated by the amazing transformation of a bunch of homely pellets – or “nurdles” as they are called on Confer’s – into useful, enjoyable products such as kayaks, swimming-pool ladders and hot-tub enclosure panels. So captivated that they wanted to know more about how that happens, what about the pliant nature of plastics and the electric, hydraulic and mechanical forces in the machinery makes it all possible.

When, fresh out of school, I joined the staff of Plastics Technology, I was motivated by a hunger to see how things really work, to learn what goes on “behind the scenes,” so to speak, to put all those cars on the road, packages of food on store shelves, and innumerable useful objects in every room of my home. That’s the kind of eagerness for knowing and participating in the real world of making things that we should encourage in today’s generation that’s so absorbed in apps and e-this and e-that as substitutes for physical interaction with people and their environment. Success in that effort would be good for young people, good for society and good for plastics.

Related Content

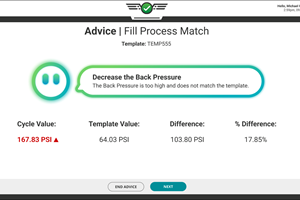

Smart Assistant Bridges Injection Molding Skills Gap

NPE2024: MAX the Process Advisor, as well as free presentations and training by RJG Inc.

Read MoreKraussMaffei and NIAR Propel Injection Molded Thermoplastic Composites

The maker of plastics processing equipment has placed a machine and an injection molding expert in NIAR’s ATLAS lab in Wichita, Kansas, to help molding, composites and aerospace take off.

Read MoreAIM Institute Continues to Grow Plastics Education and Training on 10th Anniversary

The AIM institute was created in response to the rising need for skilled injection molding professionals, providing individuals with a fundamental understanding of plastic rheology and plastic flow through a mold.

Read MoreCommunity College Launches Injection Molding Bootcamp

Nebraska’s Central Community College, which has become a centrally located training hub, successfully launched a plastics bootcamp this summer, boosting available workforce for regional molders.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More