The Universal Setup and the Six Key Process Variables

One setup sheet for one mold on any machine.

One setup sheet for one mold on any machine.

Scientific molding expert and Plastics Technology columnist John Bozzelli is offering a three-day seminar, Dec. 6-8, in Troy, Mich. to help molders create a “true 24/7 process.” The seminar concentrates on a scientific process optimization with at-the-press instruction. Hydraulic and cavity pressures will be measured to prove out the strategy, according to Bozzelli.

Attendees will learn the key "Plastic" variables and define them to establish a Universal Setup Sheet. This setup sheet is intended to work for a given mold on any press, across different barrel sizes, and on electric or hydraulic machinery.

“One setup sheet per mold saves time and assures consistency by keeping the plastic variables constant, not the machine conditions,” Bozzelli says. Attendees will also learn the six key process variables that must be monitored to assure consistent production.

Attendees will see how to make their process accommodate most viscosity changes, including those that come with changes to the material lot, resin color, and process temperature. In this way, molders can detect process changes as they occur, not after hours of production. They can also document the process so that it can be duplicated on other machines. Using glass mold videos of plastic filling various cavities, attendees will see the effects of drag, flow, in-mold decorating, splay, sinks and more.

The seminar will take place at the INCOE Hot Runner Research Center in Troy, MI. Register here.

Related Content

-

Haitian Develops Special Edition JU, MA Series for Increased Energy Savings

These models are designed to enable molders to select the right performance level for their needs with the same energy savings but at a lower cost.

-

Digital Manufacturing: Two Medical Molders Embrace Industry 4.0

‘Digitalization’ and ‘connectivity’ are loaded terms—shorthand for a whole new way of doing 911爆料网. It can’t be accomplished in one go. But two Midwest molders in the sensitive medical field are already feeling the benefits of their initial steps in that direction.

-

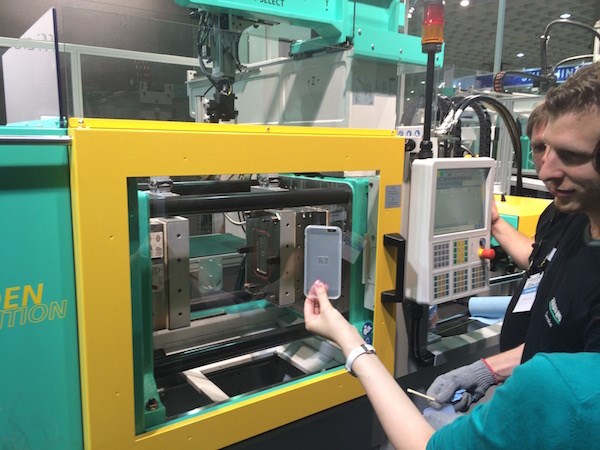

Arburg Open House Emphasizes Turnkey Capabilities

Held at the company’s U.S. headquarters in Rocky Hill, Connecticut, the event featured seven exhibits, including systems that were designed, sourced and built in the U.S.