Tool Time at Molding 2016

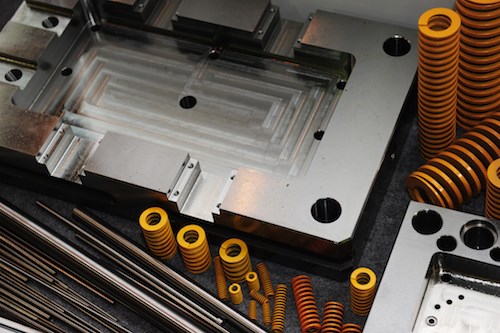

Plastics might replace metals in various applications, but in injection molding those parts require steel-based tools to be created, putting molds, and metal, at the center of the process.

Plastics might replace metals in various applications, but in injection molding those parts require steel-based tools to be created, putting molds, and metal, at the center of the process.

At Molding 2016 (March 29-31; New Orleans) maintenance, hot runners (advanced monitoring and sequential valve-gating), 3D scanning, spot cooling, multicomponent mold transfer, tungsten carbide core pins and the economics of offshore tooling are all on tap in a special Tooling-focused session.

Speakers in the session hail from molders, moldmakers, hot runner suppliers, component suppliers and an inspection firm, giving attendees a broad perspective from across the tooling supply chain with presentations that touch on all segments of a tool’s life from and design and operation to maintenance and inspection.

To mold plastic parts, you need to cut steel—find a better way at Molding 2016:

Molding 2016 Tooling Session

Randy Kerkstra, Plastics Technology columnist and tooling manager for a large, multi-plant molding company

Designing Molds for Easy Maintenance in the Press

Dave Morton, VP sales hot runners Americas,

Take Better Control of Your Molding Process with Advanced Monitoring Systems

John Blundy,

Improving Surface Finish and Part Performance Through Sequential Valve-Gate Injection Molding

John Krieg,

How 3D Scanning Technology Can Save Time in Qualifying Molds and Process

Scott Kraemer,

The Value of Hybrid Additive Manufacturing and Spot Cooling in Injection Molding

Alan Trojanowski, Zahoransky USA, Inc.

Precision in Multi-Component Mold Transfer Adds Value

Darcy King,

The True Cost of a China Mold

David LeMaistre, Crafts Technology

Faster Cooling with Tungsten Carbide Core Pins

Related Content

-

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

-

Design Your Tools for Moldability ... and Maintenance

In the initial design phase, when considering the structure and elements of the tool, are you designing them to be maintenance friendly? Canon Virginia has used this approach and preventive maintenance to make tool replacement a thing of the past. You can, too. Here’s how.

-

Scaling New Heights With Vertical Integration

Eden Manufacturing was founded on a vision of vertical integration, adding advanced injection molding capabilities to a base of precision moldmaking and more recently bringing Swiss-type machining capabilities in-house.