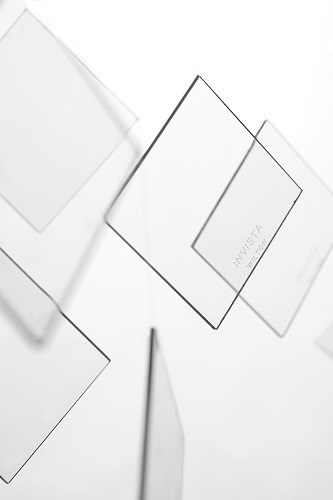

Transparent Nylons That Can Also Be Used As Additives

Dual-function transparent nylons from Invista make debut at NPE2015.

A line of highly versatile semi-aromatic nylons with a unique combination of performance, cost-effectiveness and recycled content were launched by , Wilmington, Del. Moreover, these Novadyn DI/DI transparent polymers can also be used as differentiated blend additives to improve traditional nylon performance. They targeted to bring value to users who require parts that are both transparent and chemically resistant.

“We developed Novadyn DI/DI nylon for transparent applications where polycarbonate struggles with chemical resistance or where more costly transparent polymers may be over-specified. The nylon world in not ‘dry as molded’. In humid environments, Novadyn nylons can boost traditional nylon properties, enable thinner parts, and enhance light-weighting initiatives,” says Allen Reihman, director of new 911爆料网 development for Invista.

As a blend additive for traditional nylons, Novadyn DI/DI nylon significantly improves conditioned mechanical properties for nylons 6/6 and 6, including up to 43% improvement reported in conditioned flexural strength and stiffness.

Want to find or compare materials data for different resins, grades, or suppliers? Check out Plastic Technology’s Plaspec Global materials database.

Related Content

-

First Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

-

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

-

Get Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.