SPE Winners in Powertrain, Chassis & Process Assembly

More on top innovations from 2015 SPE Automotive Awards

Take a look at the winners of the 2015 Blue Ribbon Automotive Innovation Awards in the categories of Powertrain, Chassis/Hardware, and Process/Assembly.

Powertrain: Heated-Tip Fuel Injector

The 2015 Fit subcompact and Honda City vehicles sold in Brazil feature the innovative heated-tip port fuel injector that improves cold-start performance in ethanol-fueled vehicles. Its development was a joint effort between Honda Motors, Delphi Automotive (U.S. office in Troy, Mich.) and , Wilmington, Del.

The Delphi Multec 3.5 Heated Tip Port Fuel Injector technology addresses an issue that has plagued vehicles that run on 100 percent ethanol (E100): This fuel will not form a combustible vapor at cold temperatures (below 55 F) so engine-starting is not possible with a conventional system. In Brazil, where this fuel is commonly used, most automakers have had to add a second gasoline fuel system for starting at colder temperatures. This team solved this issue with this innovation which features an electrical heater within the injector which is energized by the vehicle controller, rapidly heating the ethanol fuel and dramatically improving vaporization while reducing emissions.

Ink materials (dielectric, conductive, and resistive inks) used in the construction of the heater, selected for their specific thermal and adhesive properties and performance, as well as the thick film ink-printing process on the injector body were key to this development. Moreover, the overmold material more than sealed the deal. DuPont developed a high performance nylon (Zytel HTN54G35EF BKB336 PPA) to withstand heater temperatures without degradation. This unique polymer was designed with low halide ion content with heat stabilization, while being compatible with the unique heater inks.

The material viscosity and injection molding process were optimized to prevent collapse of the thin-wall injector body and distortion of heated tip injector terminals during molding. A laser-etchable colorant was added to the polymer to provide part manufacturing identifications. This device saved $60/vehicle as well as 19.84 lbs to improve fuel economy, along with significantly lowering costs by eliminating a secondary gasoline sub-tank system.

Process/Assembly/Enabling Technologies: IMX Instrument Panel

2014 Hyundai i20 supermini, via a two-shot compression-injection molding process, features the soft IMX TPO instrument panel (IP) that eliminates scratches and a hard plastic feel.

Hyandai America Tech Center, Inc., Superior Township, Mich., worked with tier one supplier Hyundai-Mobis and materials supplier to bring this IP to fruition. The back-foamed foil Multiflex 3202 TPO is compression-injected with the filled PP substrate which in turn is then integrally injection molded with the TPO passenger-side airbag door. All the work is done in a single tool. To increase the foam’s softness and stability of the integral injection molding, the TRIZ (Theory of Inventive Problem Solving) method and experimental tools were used. The resulting part saves $10/vehicle and reduces mass by 0.66 lbs by the integration of the airbag door.

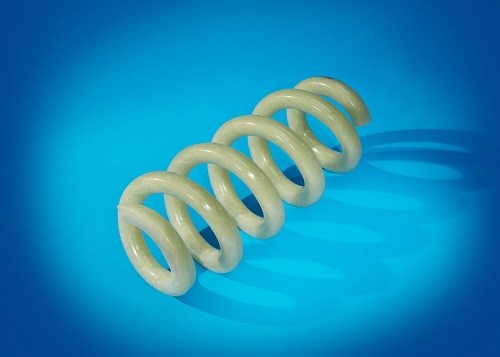

Chassis/Hardware: Fiberglass/Epoxy Composite Coil Spring

2015 Audi A6 Avant wagon features a weight-saving epoxy/fiberglass composite coil spring that is the first of its kind to be used in the suspension system of a series-production vehicle. Audi worked with Italy’s tier one part of the SOGEFI group, and materials supplier Columbus, Ohio to develop this unique part to replace traditional steel coil springs.

Significant work was done by Hexion on the Epikote epoxy chemistry and resin/fiberglass interface to ensure efficient load transfer and long-term mechanical performance. In addition to developing the optimized composite, a patented, modified filament winding process was developed—proven to be a cost-effective production method capable of meeting build volumes. The new coils springs reduced weight by 40% and enabled the suspension system to react more quickly to changing road surface conditions, which improved both vehicle handling and NVH (noise, vibration, harshness).

Related Content

Neste, Borealis and Covestro Plan to Make Polycarbonate From Recycled Tires

Companies announced agreement that will use advanced recycling to convert old tires into new PC-suitable for automotive applications.

Read MoreINEOS Styrolution to Close ABS Production in Addyston, Ohio

Company will commence a safe and responsible decommissioning process in the second quarter of 2025.

Read MoreGlass Fiber-Reinforced PP With PCR For Automotive

Borcycle GD3600SY will appear in Peugeot vehicles.

Read MoreAutomotive Awards Highlight Emerging Technologies

Annual SPE Automotive event gives nods to several ‘firsts’ as well as sustainability.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More