Appliance Growth Slowing

Current growth rate in production is strong, but the dip in housing permits could change things.

Since May 2012, appliance production has grown in all but about 12 months. In our last update in October, we noted the leading indicators were pointing in a positive direction for the industry.

But the indicators have turned in the last six months. Here’s what’s going on:

Real 10-Yr Treasury Rate. The real (inflation-adjusted) 10-yr U.S. Treasury bond interest rate was 0.92% in February, which was a slight decline from last month. This was the first month below 1% since November, and it was the lowest rate since October. The nominal rate currently was 242 basis points (2.42%), which was virtually unchanged from last month. But the rate of inflation rose to its fastest rate since February 2012. In February 2017, inflation was above 2.5% for the second straight month. Increasing inflation is limiting the rise in the real 10-yr Treasury rate even though the nominal rate has increased (the real rate is the nominal rate minus inflation). The year-over-year change in the real rate increased to -53 basis points (-0.53%). That was the fourth straight month of an increase and the highest it has been since May 2016.

The interest rate is an extremely important indicator for the appliance industry because of its significant impact on the housing market. Generally, a lower rate either encourages refinancing of mortgages, providing cash for home improvements, or it makes the monthly payment of a new mortgage lower, which tends to spur activity in the market. Either tends to lead to purchases of new appliances.

Housing Permits. There were 84,500 housing permits filed in February 2017. This was the lowest level for permits since January 2016. Compared with one year ago, housing permits were unchanged, which was the second time in three months that permits did not grow. The annual rate of growth decelerated to 0.3%, which was the slowest since October 2011.

Housing permits tend to lag changes in the real 10-yr Treasury rate by about one year. Since October 2016, the change in the interest rate has been moving in a negative direction for housing permits. Therefore, I expect the annual change in housing permits to contract at some point in 2017.

Appliance Industrial Production. Despite the extended period of growth since May 2012, the actual level of appliance production is still at the bottom of the production levels from 1994 to 2007. That shows what a toll the industry took as a result of the popping of the housing bubble about 10 years ago.

In February, appliance production was up 2.4% from where it was one year prior. That was the slowest rate of month-over-month growth since March 2016. The rate of growth has slowed significantly since last fall. As a result, the annual rate of change in appliance production (see graph) grew at a slightly slower rate in February. While the current growth rate is quite strong, I expect the growth in appliance production to slow throughout 2017.

ABOUT THE AUTHOR: Steven Kline Jr. is part of the fourth-generation ownership team of Cincinnati-based , which is the publisher of Plastics Technology. He is currently the company’s director of market intelligence. Contact: (513) 527-8800 email: skline2@gardnerweb.com; blog: gardnerweb.com/economics/blog

Related Content

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreMultilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

Read MoreBMW Group Vehicle to Adopt 3D Printed Center Console

A vehicle coming to market in 2027 will include a center console carrier manufactured through polymer robot-based large-format additive manufacturing (LFAM).

Read MoreRead Next

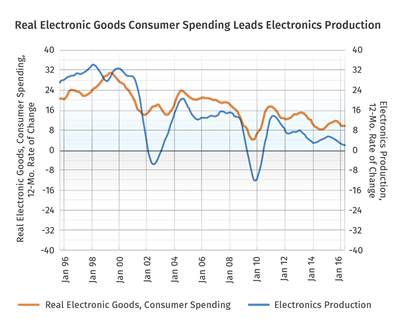

Growth in Electronics Production to Remain Weak

Spending on electronics has been growing, but the pace is probably not sustainable.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More.JPG;width=70;height=70;mode=crop)