Association of Plastics Recyclers Recognizes Cavitated PE Technology

Void Technologies’ VO+ PE Masterbatch Technology Achieves Critical Guidance Recognition

announced it has received Critical Guidance recognition from the APR for its proprietary process to create low density cavitated films, confirming its compatibility with PE film recycling in the US.

The VO+ technology creates micro and nano-scale air pockets in plastic, creating a film with a reduced environmental footprint.

Void’s film technology supports downstream recyclability.

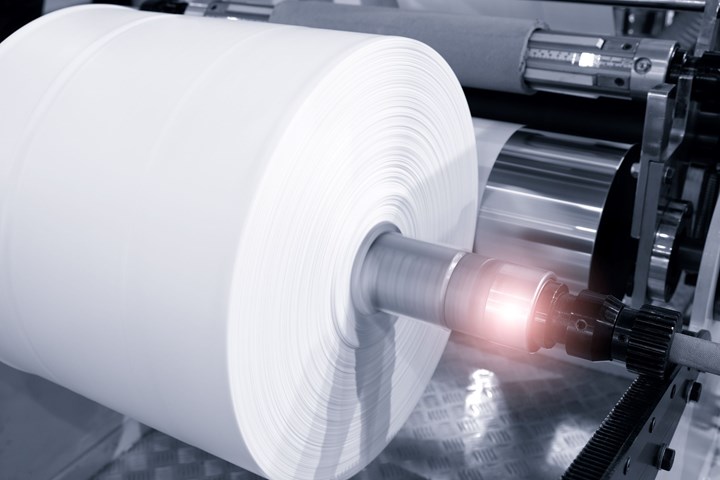

Photo Credit: Void Technologies

VO+ films are produced by blending the masterbatch with PE as part of the film extrusion process. The orientation process causes the VO+ additives to separate from the primary polymer to create a non-breathable voided structure. The combination of MDO and cavitation leads to improved film performance including puncture resistance, toughness, and high opacity.

PE films produced using Void’s new process offer a 35% material savings from density reduction and down-gauging.

The APR recognition comes after laboratory testing confirmed that the technology is compatible with current, industrial-scale, film to film recycling processes. Thanks to the low density of VO+ PE films, they will float in separation systems. During the recycling process, VO+ films will turn from white to clear and will retain similar properties to recycled PE resins.

Void’s VO+ PE masterbatch technology was developed for use in a range of applications such as laminates, frozen food, wicketed bags, and flow wraps for confectionery.

Related Content

-

US Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

-

Get Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

-

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.