Betts Retires from Wittmann Battenfeld

Working in plastics for more than 40 years, Tom Betts announced his retirement from Wittmann Battenfeld.

Tom Betts, who most recently worked in Michigan as a regional sales manager of injection molding machinery for Wittmann Battenfeld, has announced his retirement. Betts worked for more than 30 years for Battenfeld and then Wittmann Battenfeld and has been in the plastics industry for more than 40 years.

Betts was also active in the Society of Plastics Engineers and the Plastics Industry Association, where he was active with both the Machinery Division and the former Structural Plastics Division.

As a speaker at various industry events, Betts also delivered more than 30 papers on numerous topics, including co-injection, gas-assist molding, thermoset processing, liquid silicone rubber molding, micro-molding, physical foaming and automation.

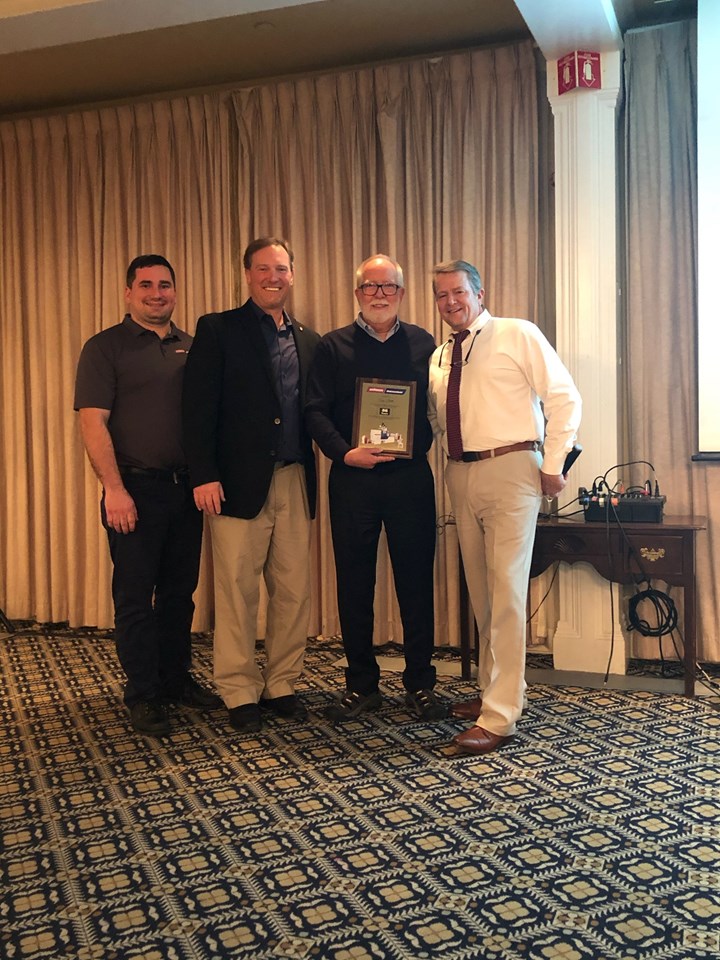

Pictured from left to right—David Sharp, Wittmann Battenfeld Operations Manager - IMM; Sonny Morneault, Wittmann Battenfeld VP-Sales; Tom Betts, and David Preusse, Wittmann Battenfeld President. “We have been lucky to have Tom on our team for many years, and we wish him all the best in his well-deserved retirement,” Preusse said in a release.

Related Content

-

Injection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

-

Use These 7 Parameters to Unravel the Melt Temperature Mystery

Despite its integral role in a stable process and consistent parts, true melt temperature in injection molding can be an enigma. Learning more about these seven parameters may help you solve the puzzle.

-

A Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.