Chemical Recycling Trials for Glass-Reinforced Nylon

Honda and Toray are jointly validating a process for recycling Nylon 6 with automotive applications.

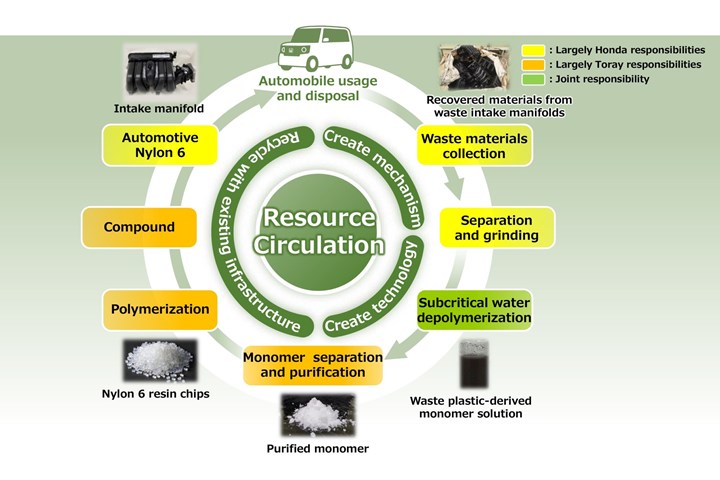

announced an agreement with to jointly develop chemical recycling technology for glass-fiber reinforced nylon 6 (polycaprolactam or PA6) parts from end-of-life vehicles. The technology entails depolymerization with subcritical water and regenerating the materials as caprolactam monomer.

Individual and joint contributions to Toray/Honda Recycling Project. Photo Credit: Toray Industries

The companies chose to focus on subcritical water for its dissolving power and hydrolysis effect on resins. According to Toray, depolymerization of nylon 6 with subcritical water can generate high yields of raw monomer. Separating, refining and repolymerizing the monomer generates nylon 6 that performs like a virgin material.

Japan’s Ministry of the Environment adopted this technology for a fiscal 2023 project to establish a decarbonized circular economy system, including validation of recycling systems for plastics and other resources. Toray and Honda look to employ that project to set up a pilot facility with a processing capacity of 500 metric tons annually of raw resin, conducting validation testing with it.

The two companies will develop depolymerization and monomer separation and refining technologies by employing intake manifolds as raw materials for engine intake system parts. They seek to apply these technologies for recycling chemicals in automotive resin parts by around 2027.

Related Content

-

Multilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

-

How to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

-

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.