Desktop Metal and Lumafield Partner to CT Scan and Print Parts

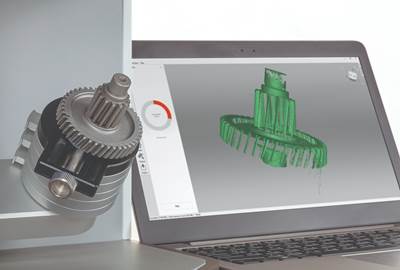

The manufacturer of 3D printers and the supplier of an industrial X-ray CT platform are coming together to address supply chain disruptions and allow manufacturers to create new parts without original CAD models.

Additive manufacturing technology supplier Desktop Metal Inc. and Lumafield, a startup supplying an industrial X-ray CT platform announced a service offering to help manufacturers quickly and accurately produce high-demand parts without original CAD models via scanning and 3D printing.

The companies note that additive manufacturing offers the ability to cost-effectively in-source production and reduce supply chain risk, but it often requires the original CAD models of the parts. 3D scanning has been proposed as a solution, but it’s limited to capturing exterior part features.

To address this shortcoming, Desktop Metal and Lumafield have announced the Supply Chain Resilience package, which joins 3D printing and X-ray computed tomography, also known as CT scanning. Together these technologies allow manufacturers to scan old parts and reproduce them quickly in a variety of materials using 3D printing.

Lumafield’s CT platform digitizes parts with a series of X-ray images that capture both external and internal features in detail. It then uses cloud-based software to create a 3D model that can be exported as a mesh representation for 3D printing. Desktop Metal’s software and 3D printers can then turn those mesh models back into metal or polymer parts.

In a release, Ric Fulop, founder and CEO of Desktop Metal noted that for manufacturers who have wanted to replace legacy fabrication processes with 3D printing, digitalization of parts has been a barrier. “With accessible CT scanning, we finally have the digitization solution we need to quickly convert old designs into complete CAD files for 3D printing,” Fulop said.

Eduardo Torrealba, co-founder and CEO of Lumafield, said in a release that this package aims to address ongoing supply chain difficulties. “The last two years have been profoundly disruptive,” Torrealba said in the same release, “and we cannot expect our supply chains to return to normal.”

Customers interested in pairing a Lumafield scanner with a Desktop Metal printer can customize a package to fit their needs. Desktop Metal will offer all of its metal printers, including the Desktop Metal Shop System, as well as all ETEC DLP polymer 3D printing systems, which includes the D4K, P4K, Envision One XL or Xtreme 8K.

Lumafield’s Neptune scanner is designed to work at home or any office or workshop environment. It features a touchscreen control and AI-powered configuration. The company’s cloud-based Voyager software is included with every Neptune scanner. In addition to producing mesh exports for 3D printing, it offers visualizations that reveal invisible features, measurement tools for inspection, and an automated analysis engine that pinpoints voids, pores and cracks before they become critical problems. Voyager runs in the cloud and is accessible through any desktop web browser, allowing teams to collaborate in real time.

The package is available to any customer that purchases a Desktop Metal 3D printer and reserves a Lumafield CT scanner between May 1 and July 1, 2022. Customers will be entitled to a package benefit of 15 CT scans and application engineering support through Lumafield’s scanning service while they wait for delivery of their Neptune scanner, currently expected to take place in the fourth quarter of 2022.

Customers interested in pairing a Lumafield scanner with a Desktop Metal printer can customize a package to fit their needs.

Photo Credit: Desktop Metal

Related Content

NPE 2024: Additive Manufacturing Assisting, Advancing Plastics Processing

Exhibitors and presenters at the plastics show emphasized 3D printing as a complement and aid to more traditional production processes.

Read MoreSmooth Operators: Vibration Compensation Improves Robot Performance

Ulendo is working to apply its vibration compensation algorithm to robots. This application is more complex than its initial market of fused filament fabrication 3D printers, but could result in faster, cheaper robots.

Read MoreFreeform Injection Molding Eases the Path to Medical Device Product Testing

A development and manufacturing service provider is using dissolvable molds to build injection molded silicone prototypes.

Read MoreBMW Group Vehicle to Adopt 3D Printed Center Console

A vehicle coming to market in 2027 will include a center console carrier manufactured through polymer robot-based large-format additive manufacturing (LFAM).

Read MoreRead Next

Desktop Metal Acquires Adaptive3D

This acquisition provides entry into the large and high growth elastomers market, one of the growing applications for additive manufacturing.

Read MoreNext-Generation Industrial Desktop 3D Scanner for QC

Exact Metrology’s newest version of Artec Micro boasts ultra-high precision.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More