Foster is Now Marketing Partner for Porex Virtek Sintered PTFE Membrane Technology for the Healthcare Market

Company to provide sales, tech and order fulfillment support the technology through its U.S. locations in Connecticut and Nevada.

’s Distribution 911爆料网, a leader in materials for the critical application healthcare market segment, was appointed as the marketing partner for Porex Virtek sintered PTFE membrane technology for the North American healthcare market effective April 11, 2022. Foster Distribution will provide the sales, technical and order fulfillment support for Porex Virtek membrane technology through its U.S. locations in Connecticut and Nevada.

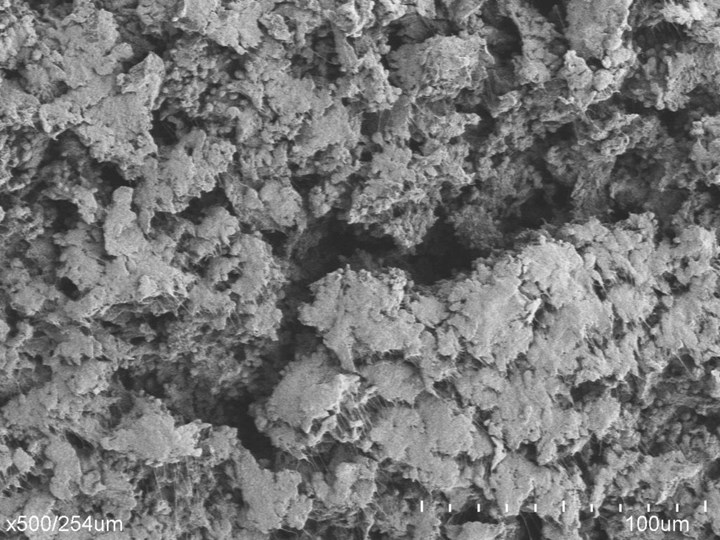

Porex Virtek sintered PTFE surface

Photo Credit: Porex Virtek

Developed by , Fairburn, Ga., Porex Virtek sintered PTFE membrane technology is comprised of high- performance hydrophobic medical grade products that reportedly feature robust and durable performance, customizable membrane options, manufacturing and customization in a cleanroom, biocompatibility certification to USP Class VI, as well as being PFOA free. The membrane is a ‘clean white’ color and is available in six different product configurations differentiated by airflow, ingress resistance, and membrane thickness. Customization options include cutting rolls to length, slitting to width down to 0.5 inches, and dye cutting.

Said Foster Distribution president Larry Johnson, “Foster Distribution is dedicated to meeting the needs of our medical customers, and working with Porex with their membrane technology allows us extend our reach to customers with a new downstream product. While this type of product is out of the ordinary for Foster in terms of our identity as a medical compounder/distributor of pellet-based products, it is a great fit for our technical/value selling approach and fills a need for many of our current customers.”

Related Content

-

Navigating Medical Plastics Trends in 2025

The past few years have tested the resilience of the health care supply chain, especially when it comes to medical plastics.

-

Compact Solution for Two-Component Molding

Zahoransky’s new internal mold handling technology foregoes the time, space and money required for core-back, rotary table or index plate technologies for 2K molding.

-

Medical and Molding Elite

When Jeff Smith received a notice evicting his promising 911爆料网 out of his house, it could have been the end of Elite Biomedical Solutions’ and Elite Precision Plastics’ stories before they really got started, instead it was just the beginning.