'World's Largest' 3D Printer ‘Farm’ to Compete with Injection Molding

Slant 3D’s new headquarters reportedly will be the world’s largest 3D printing facility.

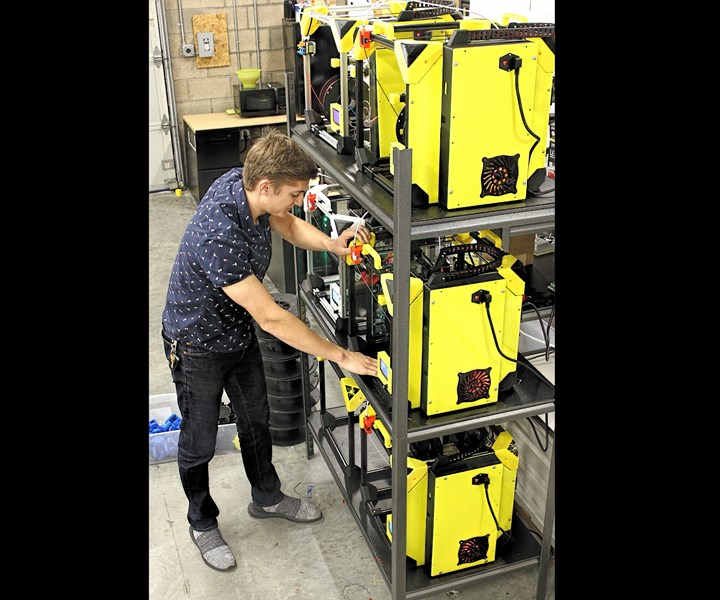

Slant 3D, a 3D printing startup in Nampa, Idaho, says it is building what will be the largest 3D printing factory in the world. Slant 3D has been doubling in size every year since its inception. Its current 3D “printer farm” in Nampa has around 200 printers (double the number when we reported on them in a Jan. ’18 Close-Up), which can produced up to 10,000 parts/week at a cost competitive with injection molding. The new plant, in nearby Caldwell, Idaho, will have 800 printers, including those moved from Nampa, which will be around 300 more than the world’s largest 3D printing facility today, according to Slant founder and president Gabe Bentz. The new building—with about 5000 ft2 of manufacturing space, plus offices—will become the company’s new headquarters when it opens in late February. The entire factory will be fully automated, with only a handful of technicians to keep it running. Bentz plans to open similar factories around the country.

Slant 3D plans a “farm” of 800 3D printers in Caldwell, Idaho.

“3D printing makes the first part for about $10, and at high volumes can match the per-part cost of injection molding,” says Bentz. His firm produces mainly hardware for agriculture and industrial machinery, along with consumer products for new startups and small 911±¬ÁÏÍøes. Slant’s machines are custom designed and self-tending. They can run 24/7 with minimal human intervention, according to Bentz. Using FDM-type filament deposition technology, its printers are said to have over 95% reliability.

Related Content

-

NPE 2024: Additive Manufacturing Assisting, Advancing Plastics Processing

Exhibitors and presenters at the plastics show emphasized 3D printing as a complement and aid to more traditional production processes.

-

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

-

Smooth Operators: Vibration Compensation Improves Robot Performance

Ulendo is working to apply its vibration compensation algorithm to robots. This application is more complex than its initial market of fused filament fabrication 3D printers, but could result in faster, cheaper robots.