Henkel and Carbon Expand 3D Printing Partnership

As part of the collaboration, the new Loctite 3D IND405 Clear material is immediately available to Carbon customers.

Henkel and Carbon announced a partnership agreement to collaborate for Loctite branded formulations validated for use with Carbon’s additive manufacturing process. As part of the collaboration, the new Loctite 3D IND405 Clear material is immediately available to Carbon customers. The partnership agreement gives industrial customers access to Henkel’s patented single-component technologies (1K) for use with the Carbon Digital Light Synthesis (Carbon DLS) 3D-printing process.

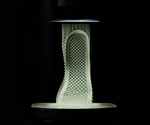

Loctite 3D IND405 Clear certified for Carbon printers is a clear, tough, semirigid, 3D-printable material. Produced as a one-part resin, the clear polymer is reportedly easily printed using the consistent Carbon DLS process. Potential applications include enclosures and housings, light pipe prototypes, bottle prototypes, jigs and fixtures for production floors and more.

“Our expanded partnership with Carbon allows us to deliver Loctite solutions to customers in the aerospace, automotive, industrial and medical markets. Together we offer an efficient additive manufacturing workflow that facilitates the production of durable end-use parts,” said Simon Mawson, senior vice president and head of 3D printing at Henkel.

Under Henkel’s Loctite brand, the company offers a growing portfolio of resins for photopolymer 3D printing. By combining the Carbon DLS printing process with Henkel’s materials expertise and coupled with highly-vetted workflow print settings, the partners aim to drive more adoption of additive manufacturing at scale.

“We are excited to be partnering with Henkel to add this material to our portfolio of resins,” said Jason Rolland, senior vice president of materials at Carbon. “Our customers have asked us for a clear material that is tough, durable and high-impact resistant. Loctite 3D IND405 meets those needs, and we’re committed to continuing to provide product developers the widest range of best-in-class materials.”

Loctite 3D IND405 Clear has potential applications for enclosures and housings, light pipe prototypes, bottle prototypes, jigs and fixtures for production floors and more.

Related Content

-

420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle's additive manufacturing technology is designed for precision tooling.

-

5 Trends in 3D Printed Injection Mold Tooling

3D printing has moved beyond conformal cooling, and is now being applied to injection molds more broadly. Observations on additively manufactured mold tooling from the Plastics Technology Expo — PTXPO 2025.

-

NPE 2024: Additive Manufacturing Assisting, Advancing Plastics Processing

Exhibitors and presenters at the plastics show emphasized 3D printing as a complement and aid to more traditional production processes.