Lanxess Develops Concept for Radar Sensors with Integrated Thermal Management

Using its high-performance thermoplastics, Lanxess’ thermal management concept is aimed at autonomous driving.

A new concept for radar sensors with integrated thermal management that will benefit autonomous driving has been developed by Lanxess. While there is still a long way to go, driver assistance systems are increasingly set to become a key feature of future generations of cars, and 360-degree monitoring of the vehicle’s surroundings is enabled by radar waves, among other things.

The radar sensors are an essential component of distance control, lane change monitoring, collision avoidance, and blind spot monitoring systems. As the sensors have to be dust- and water-proof, they are designed as fully-enclosed systems. But this makes it difficult for heat to be effectively dissipated from the inside which can impair the performance of the electronics and durability of the sensors. Said Gregor Jaschkewitz, application developer in Lanxess’ High Performance Materials (HPM), “This is why we developed a concept that allows heat to be dissipated by means of thermally conductive plastics in combination with metallic cooling elements. The individual sensor components are assembled using integrated snap fits and hot rivets, a process that is much less costly and time-consuming than using screws.”

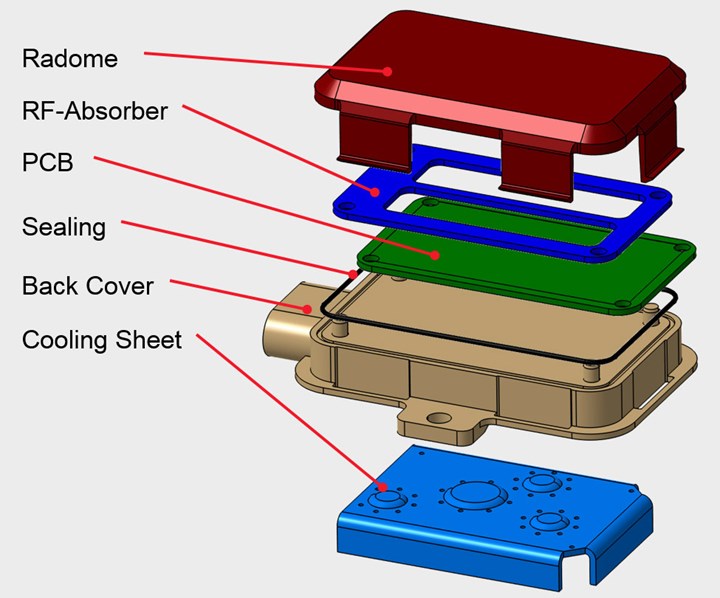

For a radar sensor, Lanxess’ concept involves the following individual components: a front cover (“radome”), radar absorber, printed circuit board (PCB) including antennas, and back cover with an integrated cooling element. The radome faces away from the vehicle and has to be made from a plastic offering a high degree of transmission for the radar waves. PBT is a well suited material here because it has a low dielectric constant (Dk) and loss factor (Df).

The back cover is the most complex part of the whole assembly. It is manufactured in a plastic-metal compound (hybrid) technique with nylon 6 and a metallic cooling element. This enables engineers to leverage the huge design freedom offered by the injection molding process, allowing them to integrate features such as reinforcement and cooling ribs as well as slots for connectors and the strain-relieved attachment of cables. Most importantly of all, however, the surface of the metallic cooling element can be overmolded with thin areas of plastic. “The heat generated on the electronic components of the PCB can be efficiently dissipated from the whole assembly through these plastic areas. This effect is supported by thermally conductive nylon 6 from our Durethan BTC product range as injection molding material,” says Jaschkewitz. Nylon 6 is also extremely tough and ductile. Another benefit of the hybrid design is that the metallic cooling element shields the electronics inside the radar sensor against electromagnetic radiation, which means that its function is not impaired by external radiation. The assembly can be sealed with O-rings or sealing lips created in a two-component injection molding process.

With most concepts for plastic radar sensors, the radome and back cover have always traditionally been made from thermoplastics that can be welded to each other to create a fully enclosed assembly. This generally meant that the same plastics had to be used for joining.the two components. “Our approach, however, places fewer restrictions on the choice of materials and makes it easier to use tailor-made compounds,” said Jaschkewitz.

Benefiting from the knowhow of a global development partner, Lanxess believes that sensors for driver assistance systems will offer a wealth of opportunities for its Durethan nylons and Pocan polyesters. “We want to benefit from the huge growth potential in this application segment and advance technological innovation with our own ideas – like the concept for radar sensors,” said Dr. Christopher Hoefs, a global application development expert in HPM. For example, the 911±¬ÁÏÍø unit also recently unveiled a concept for the modular design of charging connections for electric vehicles. HPM has pooled its extensive knowhow in material, application, process and technology development under the HiAnt brand in order to support partners and customers in projects. Said Hoefs, “We are supporting our partners at all stages of application development – from concept design, material optimization and mechanical and rheological simulation through to component testing and the start of series production.”

Related Content

NPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

Read More'Smart,' Moisture-Based Drying Technology Enhanced

At NPE2024, Novatec relaunches DryerGenie with a goal to putting an end to drying based on time.

Read MoreAI: The Next Big Thing in Plastics Processing

Discover how artifical intelligence is revolutionizing plastics processing. Hear from industry experts on the future impact of AI on your operations and envision a fully interconnected plant.

Read MoreWhat to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More