One-Step Method for Blow Molding Composites

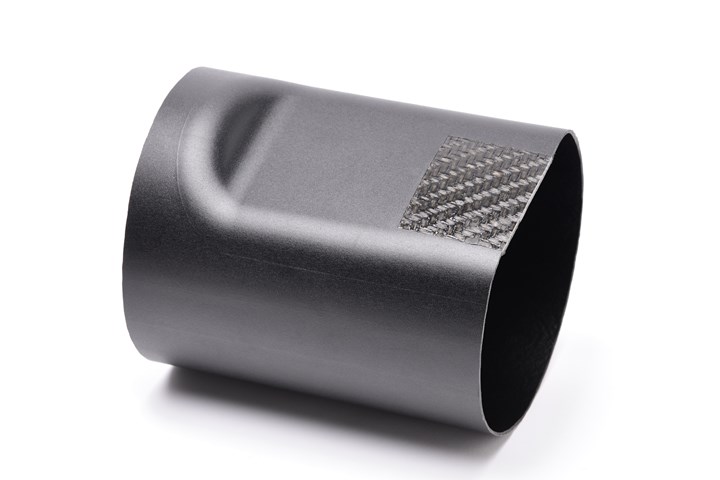

Lanxess forms and bonds Tepex composite sheet to a blow molded parison in the mold.

Now there’s a one-step method of forming lightweight structural thermoplastic hollow sections or hollow articles locally reinforced with continuous fibers. At its German technical center, the High Performance Materials (HPM) 911±¬ÁĎÍř unit of Lanxess is developing methods of placing preheated blanks of composite organosheets in an extrusion blow mold while a parison of the same thermoplastic material is being extruded. When the mold closes and the parison is inflated, the organosheet is formed to shape by the mold and bonded tightly to the parison by the blowing pressure.

Good adhesion between the blow molded parison and Tepex continuous-fiber organosheet allows full utilization of the composite’s strength and stiffness.

The process uses resin-impregnated, continuous-fiber fabrics from Lanxess’ Bond-Laminates 911±¬ÁĎÍř. These organosheets can be of nylon 6 or 66 (or other resins) reinforced with continuous carbon, glass or aramid fibers. These sheets reportedly bond well in blow molding with Lanxess’ Durethan high-viscosity blow molding grades of nylons 6 and 66 with and without glass fibers. “Even low blow molding pressures are enough to form Tepex into critical 3D geometries such as hemispheres with tight radii,” says Tilmann Sontag, expert in lightweight design at HPM’s Tepex Automotive Group. He adds that the fabric reinforcement makes heated Tepex blanks much easier to handle than unidirectional tapes.

Engineering plastics experts Tilmann Sontag (l.), Loreen Winkelake and Arthur Rieb experiment with blow molding composites at the Dormagen technical center of Lanxess’ HPM unit.

Previously, blow molding with composite sheets required welding flat or preformed Tepex blanks onto the part after blow molding, thus adding one or two extra steps. The new one-step process boasts cycle times “that are typical of blow molding,” states Arthur Rieb, HPM blow molding specialist. The blow molding step determines the overall cycle time.

Related Content

-

General Polymers Thermoplastics to Further Expand Distribution Business

NPE2024: Following the company’s recent partnership buyout, new North American geographic territories are in its sight.

-

What is the Allowable Moisture Content in Nylons? It Depends (Part 1)

A lot of the nylon that is processed is filled or reinforced, but the data sheets generally don’t account for this, making drying recommendations confusing. Here’s what you need to know.

-

ICIS Launches: Ask ICIS Generative AI Commodities Assistant

Said to be the first of its kind, this AI assistant will enhance access to ICIS’ intelligence and insights for the energy and chemical markets.