PPS Offers Toughness in Laser Welded Applications

Polyplastics’ Durafide PPS 1130A1 is said to offer greater transmittance and toughness and facilitates laser welding in a range of applications

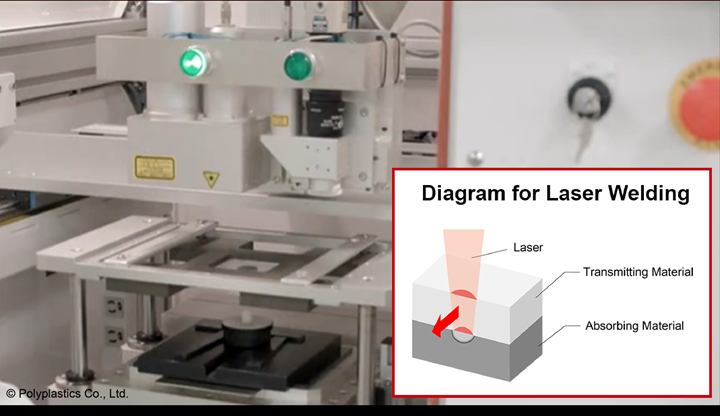

A PPS from , is finding successful use in laser welded applications such as automotive parts thanks to its enhanced capabilities. Durafide PPS 1130A1 is said to deliver greater transmittance and toughness and facilitates laser welding in a range of applications.

A joining method that offers a long list of advantages, laser welding has been difficult to actually use with PPS due to its low laser transmittance and related mass production issues such as a narrow processing window. Polyplastics’ linear-type Durafide PPS is characterized by its white natural color, as opposed to the reddish-brown natural color of competitive crosslink-type PPS materials. This reportedly gives it superior laser transmissibility (light transmissibility in the infrared region) and makes laser welding possible.

Durafide PPS 1130A1 provides approximately a 6% improvement in laser transmittance which results in a wider processing window for a broad range of welding conditions. The material also delivers an approximately 28% improvement in toughness versus standard grades. This exceptional toughness is important for initial strength and durability. The material has also been shown to offer strong dimensional stability, low warpage, and chemical resistance.

This PPS is said to enable the use of laser welding for production of automotive electric components for which this method could not readily be used before. These parts include electric water pumps, shift actuators, electric-variable valve timing actuators, solenoid valves, and various sensors.

Polyplastics is currently undertaking a development project to provide even better laser transmittance of PPS and further widen the processing window.

Related Content

-

What is the Allowable Moisture Content in Nylons? It Depends (Part 1)

A lot of the nylon that is processed is filled or reinforced, but the data sheets generally don’t account for this, making drying recommendations confusing. Here’s what you need to know.

-

Prices Bottom Out for Volume Resins?

Flat-to-down trajectory underway for fourth quarter for commodity resins.

-

The Fantasy and Reality of Raw Material Shelf Life: Part 1

Is a two-year-old hygroscopic resin kept in its original packaging still useful? Let’s try to answer that question and clear up some misconceptions.