SABIC Develops New Polymers from Recovered Ocean-Bound Plastics

Resin giant partnering with Malaysia-based plastic recycling company HHI on this initiative.

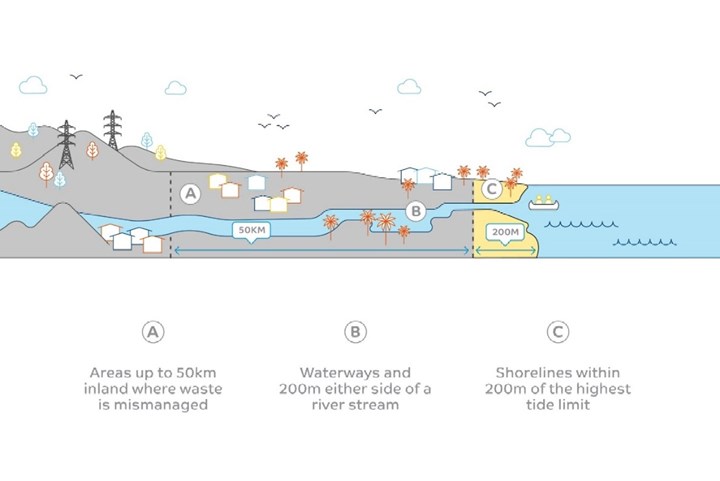

SABIC and Malaysia-based plastic recycling company HHI have announced a new collaboration to create the first certified circular polymers produced through the advanced recycling of recovered mixed and used ocean-bound plastic. The material will be used by SABIC’s customers to announce new products over the coming months. The material is recovered from ocean-feeding waterways and inland areas within a 50 kilometer radius of the ocean by HHI partners predominantly in Malaysia.

The recovered material is then sent to HHI, where they convert the used plastic into pyrolysis oil through an advanced recycling. The pyrolysis oil is then used by SABIC in their production process. The material has been certified under the Zero Plastic Oceans accreditation, and HHI is the first organization to have received certification confirming the materials it recycles qualify as ocean-bound.

“We are acutely aware of the challenges we face globally to stop plastic from becoming waste. Developing an entirely circular recycling system is a huge but necessary step we need to take together and will require all players across the value chain to collaborate. That’s why we’re committed to developing long-term solutions and working with new partners like HHI to significantly upscale the production of more sustainable materials, including those produced using recycled ocean-bound materials, for the benefit of our customers, society and the environment,” said Abdullah Al-Otaibi, general manager, ETP & market solutions at SABIC.

The circular polymers produced from ocean-bound plastic is part of SABIC’s TruCircle portfolio.

Ocean-bound plastic is material recovered from ocean-feeding waterways and inland areas within a 50 kilometer radius of the ocean. Photo Credit: SABIC

Related Content

-

Film Extrusion: Boost Mechanical Properties and Rate of Composting by Blending Amorphous PHA into PLA

A unique amorphous PHA has been shown to enhance the mechanical performance and accelerate the biodegradation of other compostable polymers PLA in blown film.

-

Multilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

-

Plastics Technology Year in Review: Your Favorite Reads of 2024

A year-end review of the top stories showcasing industry trends, advancements and expert insights. Revisit the articles that captured the attention of the plastics community.