Several PP Products Now Eligible for "Widely Recyclable" Label

How2Recycle labeling program upgrades status of PP tubs, bottles, jugs, and jars.

The How2Recycle labeling program has upgraded the eligibility of rigid PP tubs, bottles, jugs, and jars from “Check Locally” to “Widely Recyclable” in the U.S. How2Recycle says that thanks to data from the Recycling Partnership’s Polypropylene Coalition and other industry investments, it is confident this progression in eligibility continues to be aligned with the Federal Trade Commission's “Green Guides.”

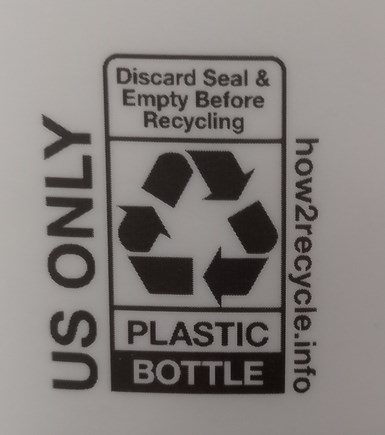

A label for widely recycled product, on a PET bottle of coffee creamer. Some PP packaging will now be eligible for this version of the label.

The FTC issued revised “Green Guides” in 2012 to help marketers avoid making misleading marketing claims. The guide states that a product can be described as “recyclable” if a substantial majority (60%) of buyers have local recycling facilities accepting it. The FTC urges consumers to confirm recyclability with their local city or county government.

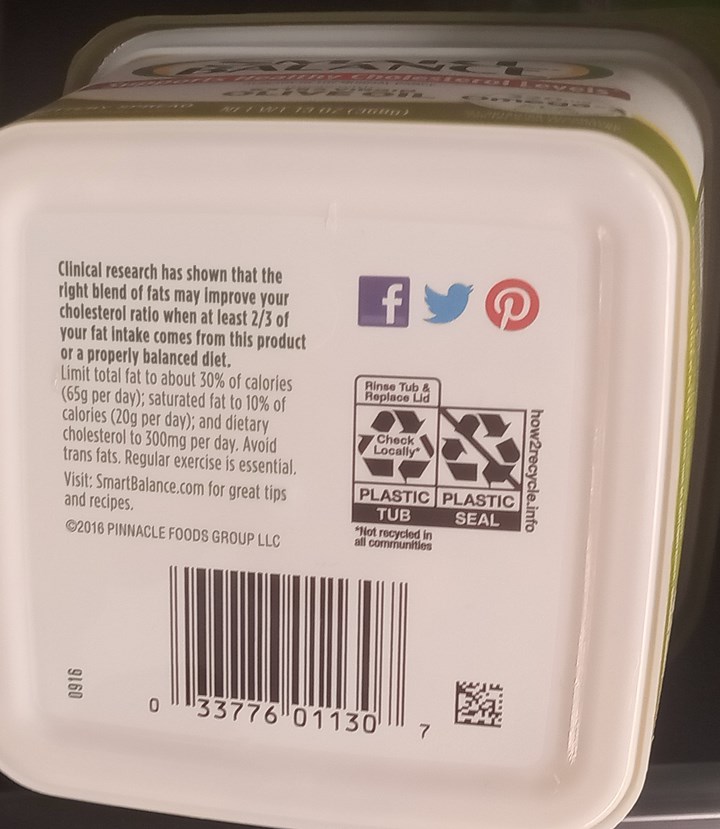

Rigid PP containers were previously downgraded to “Check Locally” in 2020, due to uncertainty around how many collection programs were landfilling or incinerating the material. Other rigid PP packaging formats, including beverage cups, remain eligible only for “Check Locally” labels. How2Recycle is pursuing additional data regarding the access to recycling and end markets of PP beverage cups to determine whether these packages should be upgraded to “Widely Recyclable” in the future.

Bottom of a PP butter tub with “Check Locally” label, with the qualifying text in the center of the universal recycling symbol.

The How2Recycle program has more than 500 members in the U.S. and Canada, including the largest producers of plastic packaging. The program assesses each package based on multiple criteria, which include how many people have access to recycle that package through curbside or drop-off programs, if the package is likely to sort and reprocess correctly, and if reliable end markets exist for the material.

Related Content

-

Multilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

-

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

-

Scaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.