Solvay, 9T Labs Partner on Bringing Carbon Composite Parts to Mass Production

The joint effort enables 9T Labs’ additive manufacturing technology to produce low-to-medium volume size parts for the aerospace, medical, luxury/leisure, automation, and oil and gas industries.

Solvay is working with 9T Labs AG (Zürich, Switzerland) to help bring additively manufactured carbon fiber-reinforced plastic (CFRP) parts to mass production.

The joint effort enables 9T Labs’ additive manufacturing technology to produce low-to-medium volume size parts for the aerospace, medical, luxury/leisure, automation, and oil and gas industries. Solvay will focus on the development of carbon fiber-reinforced polyetheretherketone (CF/PEEK), CF-reinforced bio-based high performance polyamides and CF-reinforced polyphenylene sulfide (CF/PPS) composite materials. The partnership expands the types of neat and carbon fiber-reinforced materials portfolio that 9T Labs currently offers to customers.

“With 9T Labs’ innovative process and equipment and Solvay’s high-performance thermoplastic materials, we are well positioned to address problems that have long plagued manufacturers in many industries trying to use advanced composites — namely high incremental costs, high scrap, and problems achieving repeatability and traceability at high volumes,” said Marco Apostolo, director of technology at Solvay. “We believe this collaboration will help solve many challenges and will open entirely new markets and mass production applications to CFRP materials.”

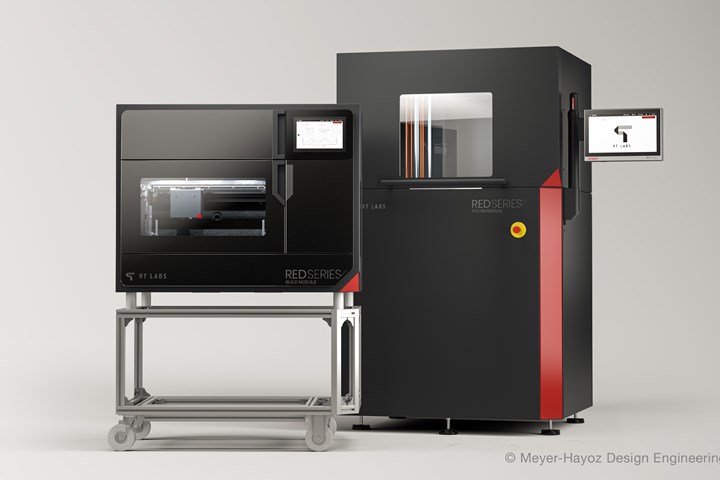

“For the fabrication of structural parts metals still prevail because the manufacturing of structural CFRP parts has not been cost-competitive,” said Giovanni Cavolina, 9T Labs’ co-founder and chief commercial officer. “The Red Series platform in combination with Solvay’s high-performance and recyclable materials will change this and make CFRP parts more sustainable, accessible and cost-competitive, especially at higher volumes.”

9T Labs’ hybrid manufacturing technology enables high-performance structural parts — in challenging small- to-medium size and thick sections — to be produced in carbon fiber-reinforced thermoplastic composites in production volumes ranging from 100 to 10,000 parts/year.

9T Labs' Red Series additive manufacturing solution. Image credit: 9T Labs.

Related Content

-

The Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.

-

How 3D Printing Supports Toolmaking Workforce at This Multiscale Molder

At more than a century old, General Pattern has seen multiple evolutions in its 911±¬ÁÏÍø — the latest of which is the embrace of additive manufacturing technologies for mold tooling and beyond.

-

Smooth Operators: Vibration Compensation Improves Robot Performance

Ulendo is working to apply its vibration compensation algorithm to robots. This application is more complex than its initial market of fused filament fabrication 3D printers, but could result in faster, cheaper robots.