TotalEnergies Corbion Publishes LCA for Recycled PLA Based on Advanced Recycling

This Life Cycle Assessment is based on recycled Luminy PLA using waste streams as feedstock for a biobased polyester.

A study recently published by TotalEnergies Corbion,“Life Cycle Assessment (LCA) of PLA through Advanced Recycling—Utilizing Waste Streams as Feedstock for a Biobased Polyester”, concludes that that the advanced recycling of the company’s Luminy PLA as a production process has a lower impact compared to its production from virgin feedstock.

Specifically, the Global Warming Potential (GWP) of Luminy 30% rPLA, considering its biogenic carbon content, is 0.19 kgCO2/kg of PLA, whereas virgin Luminy PLA emits 0.51 kgCO2/kg of PLA. Seven impact categories were considered, including GWP, water consumption, and land use. Luminy recycled PLA, integrating 20% and 30% recycled content, significantly mitigates impacts across these categories compared to virgin PLA, illustrating the environmental benefits of this pioneering recycling methodology over traditional virgin production.

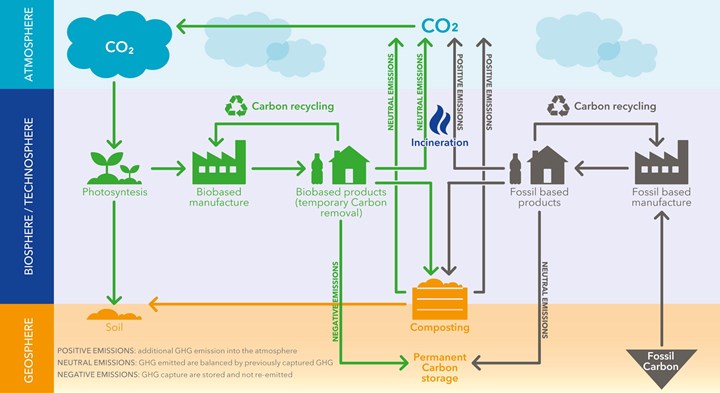

The assessment highlights the importance of considering the temporary carbon storage in products which is key for biobased materials. By analyzing the carbon cycle for both biobased and fossil-based products, the report emphasizes the role of biogenic carbon content in PLA. Recycling PLA allows a longer storage of this biogenic carbon which is originally from the atmosphere. Notably, when factoring in biogenic carbon content, the GWP of 30% recycled PLA is reduced by 300 kgCO2/rPLA compared to virgin PLA, marking a significant step towards achieving global climate targets.

Says TotalEnergies Corbion regulatory and sustainability manager Maelenn Ravard, "Depolymerizing PLA via hydrolysis is an energy-efficient process allowing us to close the loop and increase circularity for a biobased material. The LCA results only confirm this statement."

Related Content

-

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

-

PHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

-

Breaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.