Additives: Transparent Impact Modifier for rPET

Sukano’s new impact modifier masterbatch can replace specialized copolyester resins with modified recycled or virgin PET for monolayer packaging.

A new impact modifier masterbatch can replace specialized copolyester resins with modified recycled or virgin PET resin that allows processors and brand owner to produce a monomaterial and recyclable end-use product. Launched by Sukano (U.S. office in Duncan, S/C.), this is a formulated transparent impact modifier, sold under the Sukano rPET portfolio, for cold, flash frozen and room temperature applications.

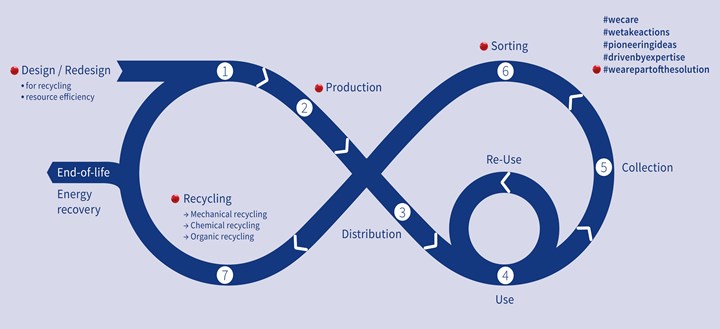

Replacing non-recyclable frozen-food trays with PET monomaterial structures, while increasing use of RPET is one key way to create sustainable solutions, say Sukano officials. They note that increased demand for plastics packaging to protect our personal health and to prevent the coronavirus from spreading further, combined with a collapse in oil prices, resulted in cheaper to produce virgin plastic. Said one source, “Given this, it is now more important than ever to consider the overarching and common goal of creating a truly sustainable and circular economy. We support our customers in switching to more sustainable solutions via our dedicated Sukano rPET masterbatch portfolio.”

Related Content

-

April 2025: Mixed Bag for Prices of Volume Resins

The end of the first quarter marked higher prices for polyolefins and relatively flat pricing for nearly all other resins.

-

Krones Acquires Netstal

Krones adds PET preform injection molding to its bottle blowing and filling capabilities, as well as cap molding and expansion into medical, food and other markets.

-

Prices Flat-to-Down for All Volume Resins

This month’s resin pricing report includes PT’s quarterly check-in on select engineering resins, including nylon 6 and 66.