At K 2022: Improved Automatic Process Control for PET Bottle Blowing

New Process Pilot+ from Agr International offers faster response and flexible goals for keeping PET bottles on spec.

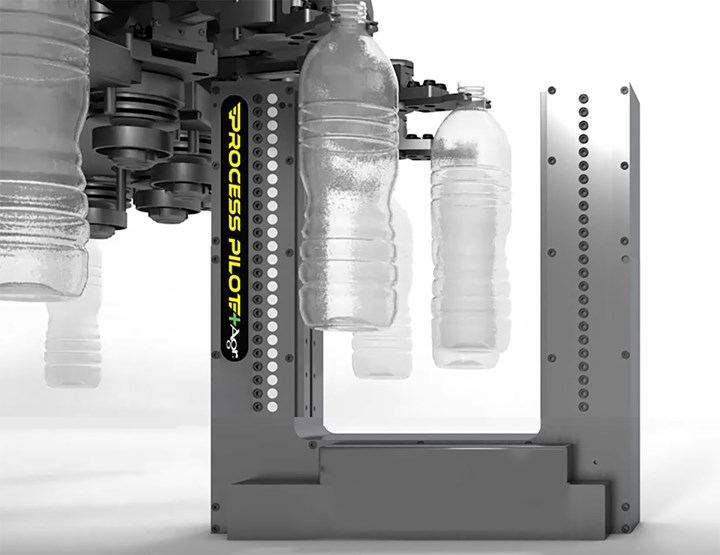

Multiple control loops in Process Pilot+ are said to correct process drift as much as 40% faster and enable startups to reach on-spec bottle production up to 65% faster. (Photo: Agr International)

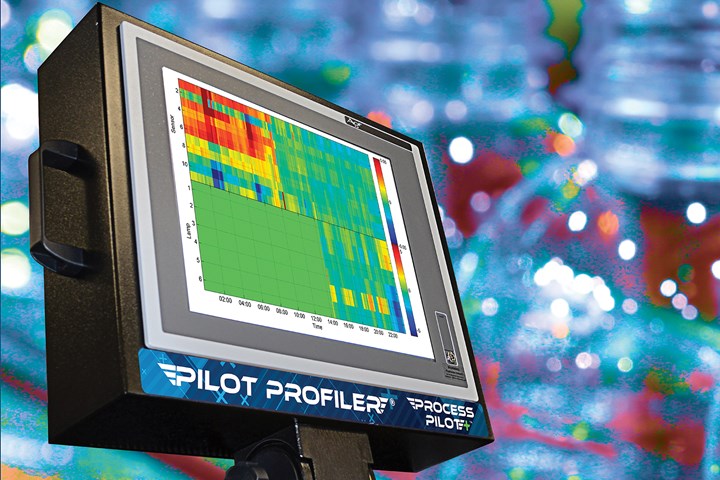

At next month’s K 2022 show in Düsseldorf, Agr International is introducing an enhanced version of its Process Pilot system for automated process management of two-stage (reheat) stretch-blow machines for PET. Like the original version, the new Process Pilot+ uses bottle wall-thickness measurements from Agr’s Pilot Profiler inline QC instrument to adjust the machine settings to compensate for changes in the operating environment (temperature, humidity), the preform quality or the material (especially variations due to the presence of rPET). The new version incorporates multiple control loops that regulate slow-response processes such as oven temperatures separately from very fast-acting processes like blow pressure and timing. The multiple control loops allow the system to correct process drift as much as 40% faster and also enable startups to reach on-spec bottle production up to 65% faster.

In addition, a new, patented Value Performance feature answers the question: “How do I make the best bottle I can for the lowest cost?” This option lets the user specify a less-than-perfect level of wall-thickness distribution that is acceptable in return for reducing compressed-air usage or energy consumption or use of lower-quality preforms.

Agr International’s Pilot Profiler measures bottle wall-thickness distribution in line with stretch blowing to permit immediate process correction via Process Pilot+. (Photo: Agr International)

Agr International also plans to introduce a new portable wall-thickness gauge at the show. The company already offers a capacitance-type gauge and a magnetic gauge. The new instrument will incorporate multiple technologies and is designed to be versatile, lower cost and more durable than existing products.

Related Content

-

Blow Molder with a Mission: CKS Packaging Shares Gains Of Its Phenomenal Growth

From three machines in 1986 to 27 plants nationwide today, this family-owned processor has prospered through unwavering customer service, committed employees and dedicated service to its community.

-

Plastics Technology Year in Review: Your Favorite Reads of 2024

A year-end review of the top stories showcasing industry trends, advancements and expert insights. Revisit the articles that captured the attention of the plastics community.

-

For Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.