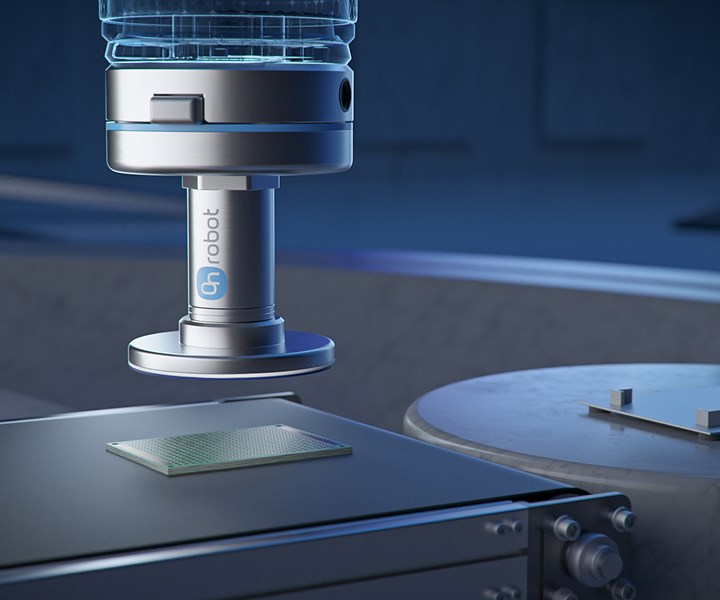

Automation: Smaller Non-Marking Gripper For Smooth, Shiny or Perforated Surfaces

OnRobot’s gripper mirrors the microstructure of a gecko lizard’s feet.

, the Danish maker of end-of-arm tooling for collaborative robots (cobots), came out with a smaller version of its novel Gecko adhesive gripper for smooth, shiny or perforated surfaces. The Gecko gripper utilizes millions of micro-scale fibrillar stalks that adhere to surfaces by means of van der Waals forces—the same way that gecko lizards are able to climb vertical walls. Because this silicone-based technology doesn’t mark even high-shine surfaces, OnRobot claims, it eliminates the need for a cleaning step in some manufacturing processes. And the Gecko grip also can grip even perforated workpieces, like printed circuit boards, aluminum mesh, or head gaskets. No wires or air supply are required.

OnRobot’s Smaller single-pad Gecko gripper can handle perforated parts like circuit boards and won’t mark shiny parts.

The new Gecko SP (single pad) gripper brings this capability to smaller applications and lighter payloads. It comes in three sizes for payloads of 1, 3, and 5 kg, vs. 5.5 to 6.5 kg for the larger, four-pad Gecko gripper. The gripper is said to offer “plug-and-play” compatibility with a wide variety of cobot brands.

Related Content

-

Golf Equipment Manufacturer Scores Higher Productivity With Automated Cell

Ping was able to reduce labor and waste at its production facility in Phoenix via an automated molding cell courtesy of Wittmann.

-

Four Industry 4.0 Tech Adoption Insights from Indiana Plastics Manufacturers

As more plastics manufacturers step into the Fourth Industrial Revolution, insights have emerged about how best to approach the digital transformation journey.

-

Smart Granulator Control Integrates Size-Reduction Systems, Enables Predictive and Knife Maintenance

NPE 2024: Conair’s New SG Control is available for its Viper Granulators